Your Complete Guide to Custom Comfort Colors Hoodies

Choosing the ideal hoodie for a custom project can be challenging, but Comfort Colors custom hoodies, with their soft feel, trendy look, and durable construction, are a top choice for those seeking quality. More than just a piece of clothing, they can also serve as a high-quality platform for corporate logos, event promotions, or personal prints. This article will delve into their core strengths, popular styles, custom craftsmanship, ordering process, and maintenance tips, explaining why they are so suitable for custom projects and providing key practical tips to help you create a satisfying custom piece.

1. The core advantages of Comfort Colors hoodie customization project

The Comfort Colors hoodie stands out in the customization field due to four core advantages, which fully meet the needs of customization from wearing experience, visual effects to long-term cost-effectiveness:

1. Enjoy "retro skin-friendly texture" right out of the box

The hoodies are made using a unique garment-dying process—they are first made and then dyed. This process allows the fabric to shrink prematurely, resulting in a naturally aged, soft feel right out of the factory, ensuring a comfortable wear experience without the need for frequent washing. Garment-dyed apparel is currently gaining popularity in the fashion and promotional apparel sectors, attracting consumers for its visual and tactile advantages, as it combines both fashion and promotional appeal.

2. Retro colors add points to custom designs

Unlike the vibrant colors of standard apparel, Comfort Colors features natural, soft Morandi hues, such as "Blue Jean," "Pepper," and "Seafoam," with a subtle faded texture. This understated background allows the custom pattern to clearly appear without overwhelming the design, lending the design a high-end, retro feel and enhancing the overall sophistication.

3. Durable materials protect custom investments

A custom hoodie is an investment, so durability is paramount. Comfort Colors hoodies are made from ring-spun cotton, which is softer and more durable than regular cotton. High-strength seams and a durable finish ensure the garment resists wear and deformation, ensuring it stays in great condition for years to come. This prevents custom patterns from prematurely becoming obsolete due to wear and tear, effectively extending the life of your custom piece.

4. Retail-grade quality adapted to diverse scenarios

Offering complete retail-grade quality, this product is a direct reflection of high quality, making it a popular choice for universities, sports clubs, small businesses, and other organizations seeking a clean, professional image. Its unique combination of comfort, color, and quality allows for flexible customization, meeting diverse needs.

2. Comfort Colors Popular Hoodie Style Comparison

Choosing the right basic style is the first step to successful customization. Comfort Colors has two core hoodies designed specifically for customization needs. The specific parameters and applicable scenarios are as follows:

| Style and model | Material and weight | Style | Adaptation scenarios |

| 1567 | 80% cotton + 20% polyester blend, 9.5 oz | Classic loose unisex fit | Strong warmth retention, suitable for year-round wear, and customized projects that pursue classic and comfortable textures (such as corporate workwear and team apparel) |

| 1467 | 80% cotton + 20% polyester blend, 7.2 oz | Lightweight, loose, neutral fit | Suitable for layering, suitable for spring and autumn or mild climates, and should avoid heavy scenes (such as spring event promotion and daily wear customization) |

3. Customization Guidelines for Comfort Colors Hoodies

Depending on the complexity of the design, order volume, and budget, you can choose from three mainstream processes: screen printing, embroidery, and direct-to-textile printing (DTG). The characteristics and practical suggestions of each process are as follows:

(1) Screen printing: suitable for bold designs and mass customization

● Process principle : Dynamically imprinting ink onto the fabric surface through a mesh screen is a traditional and mature custom process.

● Core advantages : Large orders (such as 12 pieces or more) have obvious cost advantages and can present bright and eye-catching colors; special inks can be used to achieve a soft printing effect without damaging the touch of the fabric.

● Potential disadvantages : For small orders and designs with multiple colors, the cost is higher (multiple screens need to be produced).

● Pro tip : Ask your printer to use a "soft-touch" additive or water-based ink, which penetrates the fabric fibers more easily, avoiding a heavy, plastic-like print and preserving the hoodie's natural softness.

(2) Embroidery: Suitable for high-end texture and long-lasting design

● Principle of the craft : Use needle and thread to embroider the design pattern directly on the fabric to form a three-dimensional texture with outstanding texture.

● Core advantages : visually high-end and exquisite, with a strong sense of value; the design is extremely durable, usually longer-lasting than the clothing itself, and suitable for customization of logos, text and simple graphics.

● Potential Disadvantages : Costs more than printing, especially for large designs where costs can increase significantly; cannot reproduce photographs or ultra-fine details (e.g., gradient colors, tiny lines).

● Pro Tip : The Comfort Colors hoodie is made of soft, fluffy fabric, so it's important to use a backing (or stabilizer) when embroidering to prevent wrinkling or warping, and to ensure the embroidery is smooth and precise.

(3) Direct-to-print (DTG): Suitable for full-color details and small-batch customization

● Process principle : Similar to a paper printer, ink is sprayed directly onto the surface of the hoodie to restore complex colors and details.

● Core advantages : It can present millions of colors and is perfectly suitable for detailed designs such as photos and gradient patterns. There is usually no minimum order quantity, which is suitable for single-piece customization or small-batch needs (such as personal gifts and niche team clothing).

● Potential drawbacks : The color vividness on colored hoodies is slightly inferior to screen printing; the durability is not as good as the first two processes and may fade slightly after long-term washing.

● Pro Tip : If you need to print a bright white graphic on a dark garment-dyed hoodie, choose an experienced manufacturer who will use a pre-treatment process to enhance the color rendering of the white ink. It is also recommended to request samples in advance to confirm that the print will meet your expectations.

Tips for Creating Vintage-Style Custom Designs

The Comfort Colors hoodie has a vintage feel, and the design needed to complement it to create a unified and harmonious visual effect. Key techniques include:

1. Suitable for retro colors

Avoid using highly saturated neon colors (which can clash with the hoodie’s softer tones); replace pure white with off-white or creamy white to enhance the retro feel; and extract similar colors from the hoodie’s color (such as a "denim blue" hoodie with light blue ink) to allow the design to blend naturally with the fabric tone.

2. Choose a Retro Font

Give priority to using serif fonts (with small decorative lines at the end of the letters), slab serif fonts (bold and powerful lines), or classic handwriting fonts. These fonts have a preppy or nostalgic feel, which is highly consistent with the retro tone of the hoodie.

3. Add distressed texture

In the design software, a slight "old/worn" texture is superimposed on the pattern to simulate the natural wear and tear effect of clothing after long-term wear; for example, on dark hoodies such as pepper gray and denim blue, a monochrome design is printed with off-white or light gray ink, which can not only highlight the pattern, but also highlight the texture of the fabric and the retro atmosphere.

5. Comfort Colors custom hoodies Ordering Process

Follow these five steps to ensure your customization needs are accurately implemented and avoid common errors:

1. Finalize the design and fit : Finalize the hoodie size (1567/1467), color, and finalize the custom graphic details (e.g., size, placement).

2. Prepare high-definition design files : give priority to using vector files such as AI, EPS, and PDF (which can be scaled losslessly to avoid blurry printing); if using raster files such as PNG and PSD, ensure that the resolution is no less than 300 DPI.

3. Choose a professional customization partner : Screen Manufacturers with timely customer service responses and transparent pricing. It is recommended to give priority to manufacturers with experience in Comfort Colors customization, so that you can obtain more professional process advice and quality assurance.

4. Submit the order and confirm the digital sample : After placing the order, the manufacturer will provide a digital sample (a simulation of the final product effect). You need to carefully check whether the spelling errors, design size, position and color are consistent with the requirements - this is a key step to avoid subsequent modification costs.

5. Production and delivery : After the sample is confirmed, the production phase begins. After printing/embroidery is completed, the manufacturer will conduct a quality inspection to ensure that there are no defects before delivery. After receiving the goods, sampling can be carried out to confirm that they are consistent with the sample.

6. custom hoodies Maintenance Tips and FAQs

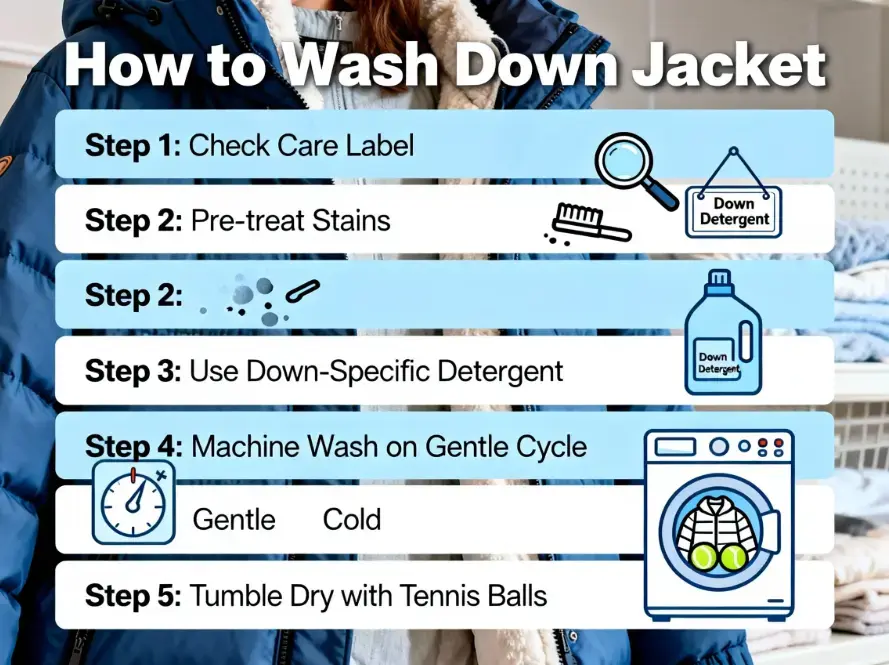

(1) Maintenance tips: Extend the life of custom hoodies

●Turn the hoodie inside out before washing to avoid friction between the print/embroidery and other clothing to reduce wear and tear;

● Wash in cold water with mild detergent. Hot water will accelerate the fading of fabrics and the aging of custom patterns.

● Choose low temperature mode when drying, or hang it directly to dry (high temperature drying can easily cause the fabric to shrink and the pattern to crack);

● Do not use bleach to avoid damaging fabric fibers and colors;

● If ironing is required, please turn the hoodie inside out and use a low heat setting. Custom patterns cannot be ironed directly on the hoodie.

(2) Frequently Asked Questions

1. Will my hoodie shrink after being custom made?

Typically not. The garment-dyeing process allows the fabric to shrink in advance, so the size will remain the same after washing. There is no need to worry about shrinkage. Simply choose your normal size when purchasing.

2. Is there a minimum order quantity for customization?

Depends on the customization process and manufacturer: Screen printing requires screen production and is suitable for batch customization of more than 12 pieces (better cost); DTG printing and embroidery usually have no minimum order quantity and are suitable for single piece or small batch needs (such as personal gifts, teams of less than 5 people).

3. Will the color of the hoodie be dyed into the custom pattern?

This is highly unlikely with custom garments. Comfort Colors' garment dyeing process is highly stable, ensuring the color doesn't easily fade. Furthermore, compliant manufacturers use inks and threads specifically formulated for the fabric to prevent color bleeding or contamination of custom patterns.

4. Is the hoodie a unisex fit?

Yes, most of our popular styles, including the classic 1567, have a unisex, loose fit that's suitable for people of all genders and body types. We recommend referring to the size chart for specific styles (such as shoulder width and length) before ordering to ensure a proper fit.

5. How to calculate customization cost?

It mainly depends on three factors: the model of the hoodie (1567 grams is heavier and costs slightly more than 1467 grams), the number of design colors (the more colors, the more screens need to be made for screen printing, and the higher the cost), and the total order quantity (the larger the batch, the lower the unit cost. For example, the unit cost of an order of 100 pieces may be 30%-50% lower than that of 10 pieces).