Unveiling Origins: Tracing the Journey of Garment Manufacturing

The global fashion industry operates as a vast ecosystem, intertwining designers, Manufacturers, and consumers across continents. For industry professionals and enthusiasts alike, decoding where clothing originates offers crucial insights. From artisanal workshops to industrial complexes, the lifecycle of apparel weaves together narratives of cultural heritage and technological innovation, revealing a story far richer than the labels sewn into its seams.

Key Takeaways

Ancient Roots:Textile craftsmanship dates back 170,000 years, with archaeological findings illuminating how garment production spread across civilizations.

Global Interconnectedness:Modern apparel manufacturing(https://site_a7d8eed0-ecc9-4af7-9b0d-717fce488edc/men-s-wear/) relies on transnational supply chains, where each stage—from raw material extraction to final stitching—spans multiple countries.

Label Literacy:Garment tags serve as more than just origin markers; they encode ethical practices and production details, fostering trust between brands and consumers.

Cultural Artistry:Regions worldwide contribute unique textile techniques and traditions, shaping the diverse landscape of fashion.

Sustainable Shift:Rising consumer demand for ethical production is driving the industry toward eco-friendly materials and low-carbon processes.

Environmental Imperative:The fashion industry’s ecological footprint, from cultivation to disposal, demands urgent green reforms across its value chain.

Garment Labels: The "Identity Cards" of Fashion

Labels function as the digital DNA of clothing, building consumer trust through transparent information disclosure. Brands adhering to labeling regulations—such as the U.S. Federal Trade Commission’s standards for fiber content or the EU’s voluntary Ecolabel for low-pollution products—empower shoppers with data to make informed choices.

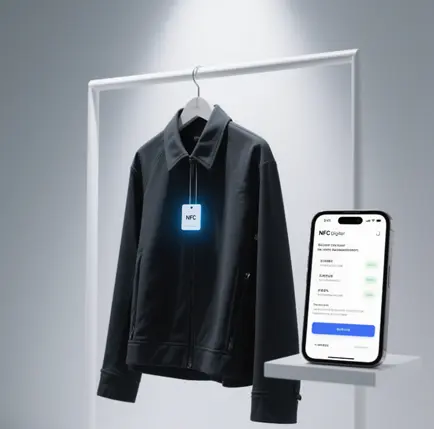

Statistics highlight their impact: Clear care instructions reduce return rates by 30%, while accurate sizing minimizes exchanges by 25%. The future promises technological leaps: NFC-enabled digital tags for instant smartphone interactions, automated material verification via devices like Fibersort, and visual sustainability metrics that resonate with 85% of eco-conscious buyers.

The Environmental Tapestry: Challenges and Solutions

The fashion industry’s ecological footprint is staggering: Cotton farming consumes 24% of global insecticides, polyester production has doubled in 15 years, and garment dyeing releases 72 hazardous chemicals into waterways annually. Yet sustainable innovations are emerging: Organic cotton reduces water use by 91%, brands like H&M source 90% of their electricity from renewables, and consumer behavior shifts—such as proper garment care (e.g., air-drying instead of machine-drying)—can extend product lifespans and cut usage-stage energy by 60%.

Production Efficiency: Knits, Wovens, and Technical Apparel

Garment types dictate manufacturing strategies: Knitted fabrics, with their looped structure, offer elasticity and faster production but lack structural rigidity. Woven textiles, with interlaced threads, provide durability at the cost of higher resource consumption. Technical sportswear presents another paradigm: Features like moisture-wicking and ergonomic cuts require specialized machinery, pushing manufacturers to balance functionality with scalable production.

Global Supply Chains: From Australian Wool to Fast Fashion Realities

The industry’s globalization is unprecedented: 80% of U.S. clothing is imported, 30% from China alone, while synthetic fibers account for over 60% of materials. The journey of Australian wool—from New South Wales pastures to European haute couture ateliers—exemplifies this network, though it also reveals environmental trade-offs (25kg CO₂ emitted per kg of wool produced).

Labor disparities remain stark: Bangladeshi garment workers earn 94 monthly, less than 17% of the 569 living wage, while the 2020 pandemic caused $57.8 billion in wage losses. The 2013 Rana Plaza collapse, which killed 1,134 workers, stands as a tragic reminder of safety failures in global supply chains.

Transparency: From Consumer Awareness to Industry Revolution

Modern consumption is values-driven: 70% of consumers prioritize supply chain transparency (Edelman), and 58% choose Ethical Brands (Deloitte). Yet gaps persist: Only 12% of major brands disclose raw material sources, 33% report full carbon emissions, and 8% address waste management.

Solutions are emerging: Circular economy models (e.g., Patagonia’s recycling programs), blockchain for material traceability, and platforms like Maker’s Row supporting sustainable startups. From Stone Age loom techniques to the Industrial Revolution’s sewing machine, fashion’s evolution proves that only by integrating human rights and ecological stewardship can the industry thrive.

Conclusion: Innovating in Heritage, Progressing in Transparency

The lifecycle of a garment—from cotton field to wardrobe to recycling facility—encapsulates humanity’s dialogue with nature. Rising ethical consumption in Europe, digital labeling for supply chain visibility, and scaling renewable energy in production signal a new era. From Bangladesh’s casual wear hubs to Italy’s luxury ateliers, the industry is rewriting its narrative: Every stitch should honor both craft excellence and the planet’s well-being.