The Comprehensive Guide to Collaborating with a Custom Clothing Maker

For clothing brand entrepreneurs, corporate workwear customization managers, or individuals pursuing personalized style, "The Comprehensive Guide to Collaborating with a Custom Clothing Maker" is a core tool for navigating the critical path from creative idea to physical garment. A high-qualitycustom clothing manufacturer not only accurately replicates design concepts and provides professional craftsmanship support, but also helps partners control costs and shorten delivery cycles through flexible collaboration models and efficient supply chain response.

Choosing the wrong partner or lacking a sound collaborative approach can lead to design deviations, inconsistent quality, and delivery delays, resulting in both time and financial losses. Dongguan Siyinghong Garment, a manufacturer with 15 years of experience in the custom clothing industry, has provided custom services ranging from casual wear to business attire to functional apparel to over 400 clients worldwide, and is deeply aware of the collaborative needs and pain points of diverse clientele.

This article will focus on "full-link practical operation" and systematically interpret "The Comprehensive Guide to Collaborating with a Custom Clothing Maker" from the dimensions of demand clarification, manufacturer screening, cooperation process, quality control and problem solving, so that your custom clothing cooperation can be controlled, efficient and smooth from start to implementation.

How to clarify customization needs and lay the foundation for cooperation with customized clothing manufacturers?

1."Clearly defining customization requirements" is the first step in "The Comprehensive Guide to Collaborating with a Custom Clothing Maker" and a key prerequisite for avoiding back-and-forth communication and demand deviations during collaboration. Many partners' initial requirements are vague (for example, simply stating "I want a batch of personalizeD Clothing"), which prevents manufacturers from accurately understanding them, resulting in finished products that fall far short of expectations.

Dongguan Siyinghong Garment recommends using a "5-Dimensional Demand Analysis Framework" to transform abstract requirements into actionable, unambiguous collaboration plans, laying the foundation for efficient collaboration with manufacturers:

2. Clarify customization goals and core scenarios: First, define the core purpose and usage scenarios for customized clothing—whether it's a brand-first, differentiated piece (must align with the target customer's aesthetic and market trends), workwear for corporate employees (must reflect the brand image and balance practicality and comfort), commemorative clothing for an event (must highlight the theme and be easily recognizable), or personalized styles for daily wear (must meet clothing preferences and fit). Different scenarios directly influence subsequent fabric selection, craftsmanship, and pattern design. For example, customized clothing for outdoor activities should focus on waterproof and wear-resistant fabrics, while business workwear should emphasize a crisp, wrinkle-resistant texture.

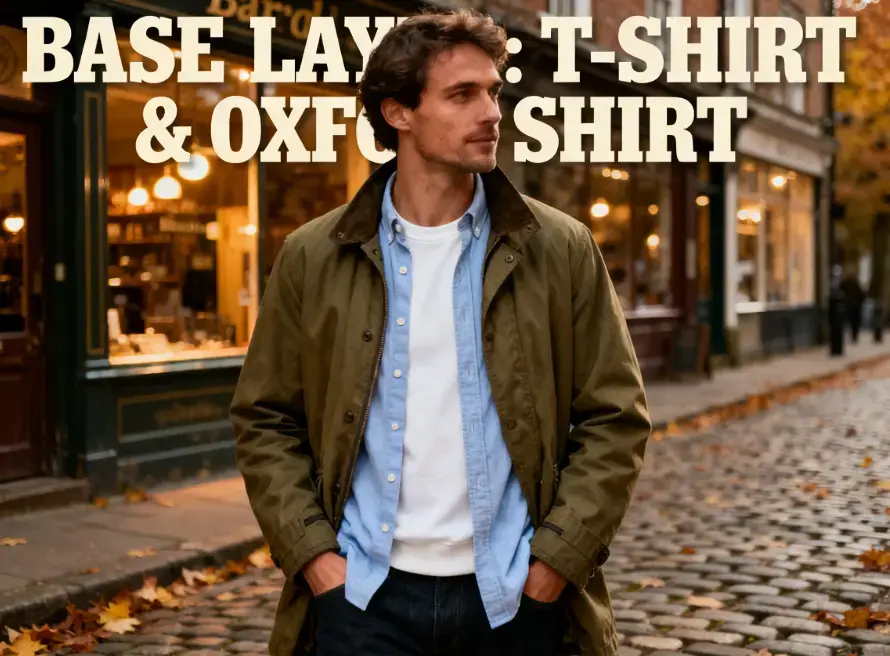

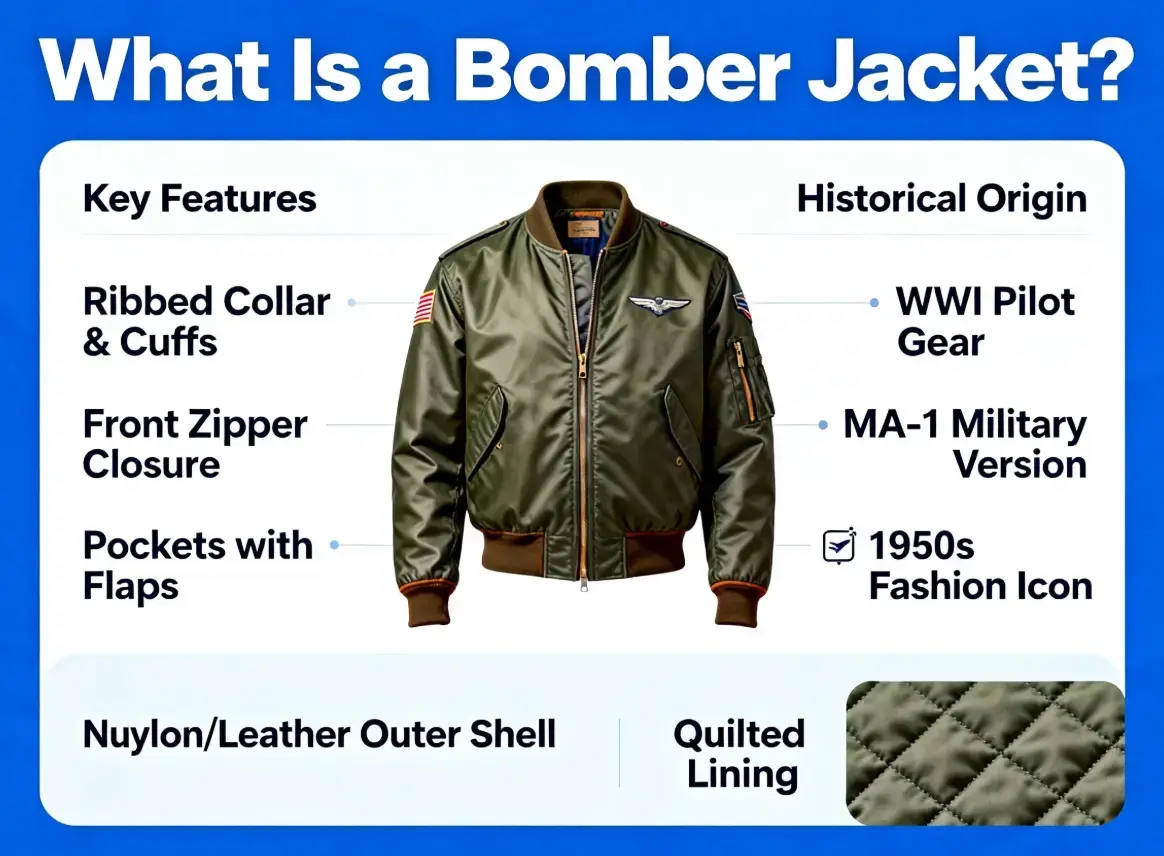

3. Identify the clothing category, style, and design elements: Clearly define the specific category of custom clothing (e.g., dresses, sweatshirts, shirts, jackets, work suits) and clearly define the style positioning (e.g., minimalist, retro, streetwear, or affordable luxury). Also, break down the core design elements, including color (provide Pantone color numbers or reference color charts to avoid color deviations), patterns (logos, illustrations, text, etc., specifying size, placement, and copyright ownership), and special details (e.g., custom buttons, contrasting stitching, detachable accessories, and exclusive embroidered logos). If a complete design plan is lacking, provide reference examples (e.g., competitor styles, fashion blogger outfits, and design sketches) to help manufacturers understand the creative direction.

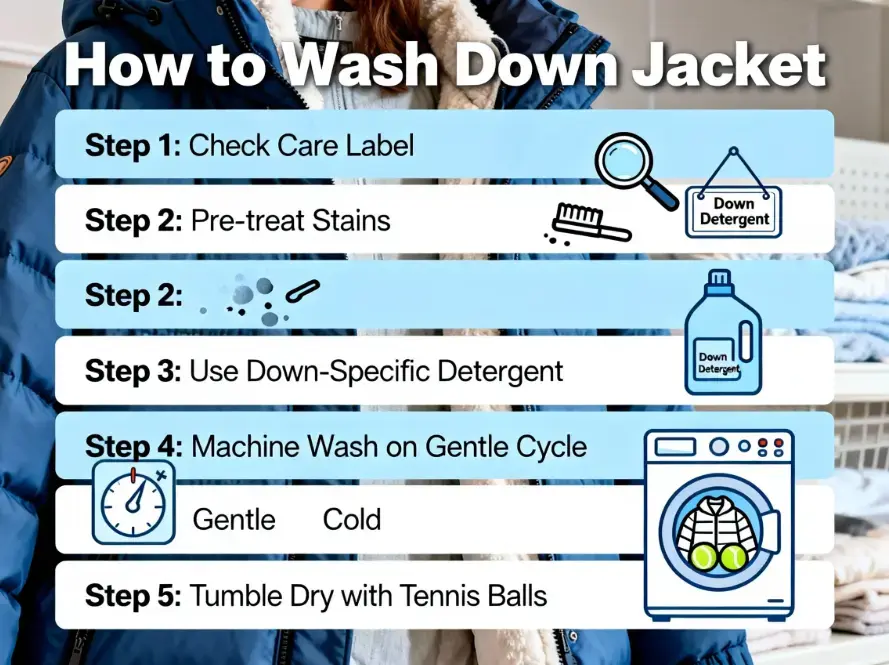

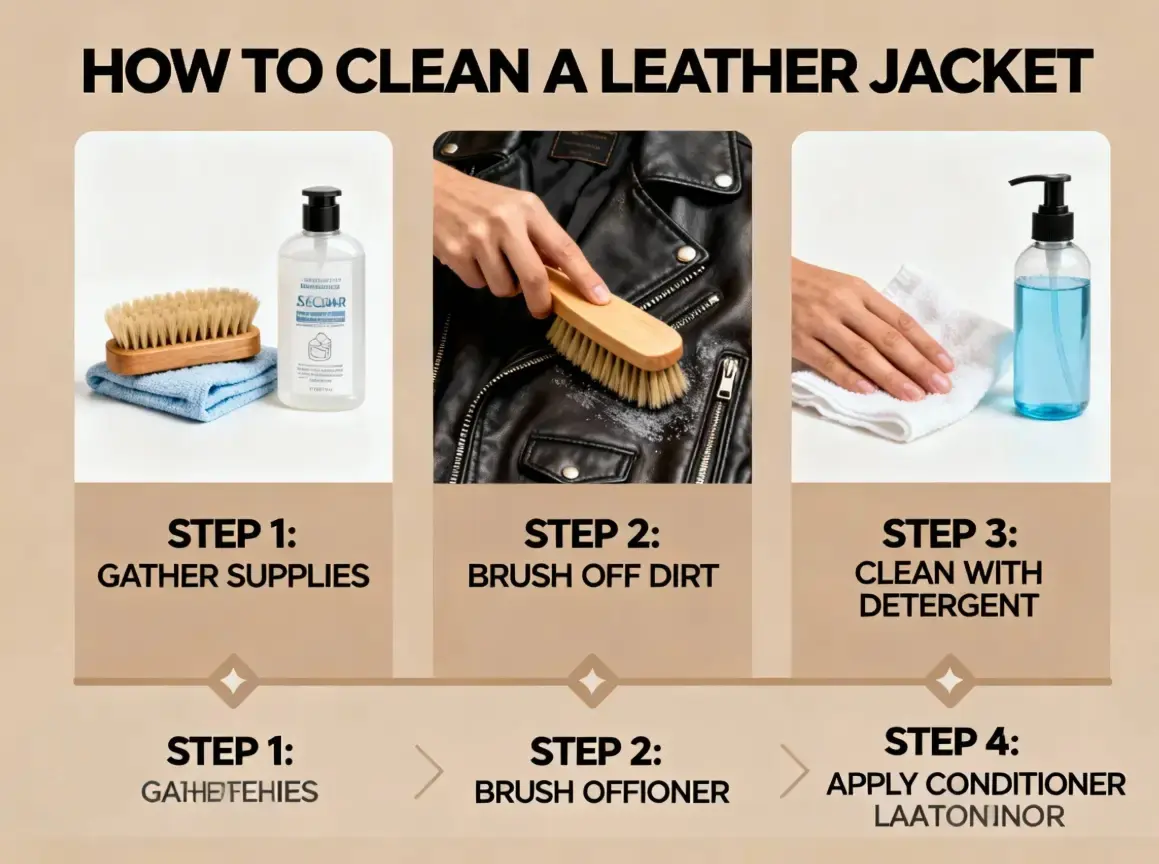

4. Determine fabric, trim, and functional requirements: Choose the appropriate fabric type based on the customization goals and scenarios. For casual wear, consider pure cotton or combed cotton (breathable and comfortable); for business attire, consider wool or polyester blends (crisp and wrinkle-resistant); and for outdoor functional apparel, consider waterproof or quick-drying fabrics (balancing protection and practicality). Also clarify fabric specifications (e.g., weight: 180-220g/m² in summer, 280-350g/m² in winter) and any special treatment requirements (e.g., shrinkage resistance, pilling resistance, and eco-friendly dyeing). Trim material selection should also be confirmed, including zippers (e.g., YKK brand), buttons (metal/plastic/wood), and care labels (including brand information, fabric composition, and washing instructions). If functional requirements are required (e.g., warmth, sun protection, or antibacterial properties), inform the manufacturer in advance so they can match fabrics and craftsmanship with the appropriate properties.

5. Clarify size range, order size, and lead time: Determine the size range (e.g., women's S-XL, men's M-XXL, custom sizes XXL-XXXXL) based on the target demographic (e.g., adults, children, specific body types), and provide a size chart reference (e.g., key measurements such as length, chest circumference, and shoulder width, with actual measurements of well-fitted garments). Also clarify the order size, whether it's a small trial run (e.g., 50-100 pieces, suitable for brand new product testing) or a large custom run (e.g., 500 pieces or more, suitable for corporate workwear or event wear). This will affect the manufacturer's minimum order quantity policy and quote. The lead time should be clearly defined in conjunction with the intended use (e.g., 10 days before an event, 15 days before a new product launch). This allows the manufacturer reasonable production and logistics time to avoid quality compromises due to tight lead times.

6. Set budget range and quality standards: Based on customization needs and market positioning, set a reasonable budget range (e.g., single-piece customization cost 50-100 yuan, 100-200 yuan) to facilitate manufacturers to recommend the most cost-effective fabrics and process solutions within the budget. At the same time, clarify quality standards, such as fabric color fastness must reach level 4 or above (not easy to fade after washing or rubbing), stitch density must be ≥8 stitches per 3cm (to ensure firmness), and the finished product defective rate must be ≤3%. You can refer to industry standards (such as GB/T 29862 clothing standards and AATCC textile testing standards), or directly agree with the manufacturer to use pre-production samples as the quality benchmark to avoid disputes over quality certification later.

Core evaluation dimensions for screening suitable custom clothing manufacturers

- After clarifying your customization needs, accurately selecting a suitable custom clothing manufacturer is a key step in "The Comprehensive Guide to Collaborating with a Custom Clothing Maker." High-quality manufacturers can efficiently fulfill your needs, while unsuitable ones can hinder collaboration. Therefore, a comprehensive evaluation from multiple perspectives is essential to avoid blind selection.

- Dongguan Siyinghong Garment has summarized six core evaluation criteria to help partners quickly identify custom clothing manufacturers that match their needs:

- Customization Capabilities and Category Focus: Prioritize manufacturers with specialized customization capabilities focused on specific clothing categories, rather than factories that offer a wide range of miscellaneous products. For example, for customizing trendy sweatshirts, choose a manufacturer with extensive experience in custom casual wear, while for customizing high-end business suits, focus on teams with expertise in formal tailoring. Customization capabilities can be assessed by reviewing a manufacturer's case studies (e.g., custom work in the same category, the types of clients served), and understanding their design team structure (whether they have dedicated custom designers and whether they can provide design optimization suggestions). If requirements involve complex processes (such as 3D printing or hand embroidery), confirm that the manufacturer has the necessary equipment and technical expertise to avoid design failures due to process limitations.

- Production Capabilities and Supply Chain Stability: Examine the manufacturer's production hardware and supply chain support capabilities—whether it owns its own factory (rather than using a middleman to facilitate control over production schedules and quality), whether it has specialized custom production lines (such as specialized equipment for cutting, sewing, and processing), and whether its monthly production capacity matches the order size (e.g., small-batch customization requires flexible scheduling, while large-volume customization requires a monthly production capacity of ≥1,000 pieces). Also, understand the stability of its supply chain, including its sourcing channels for fabrics and accessories (whether it has long-term, high-quality suppliers and can quickly source specialized fabrics), and whether it has a raw material reserve mechanism (to avoid production delays due to fabric shortages). A stable supply chain is fundamental to ensuring delivery time and consistent quality.

- Quality Control System and Records: Strict quality control is a core guarantee for custom apparel partnerships. Focus on evaluating the manufacturer's quality control processes and execution capabilities. This includes assessing whether a comprehensive quality control system, from raw materials to finished product, is in place (raw material quality inspection, production inspections, and full inspection of finished products). The manufacturer should also be asked to provide past quality control records (such as fabric testing reports and finished product spot checks), as well as examples of handling defective products. Alternatively, verify their quality control capabilities through small trial orders to avoid manufacturers without quality control processes or with inconsistent quality.

- Service Response Speed and Communication Efficiency: Custom apparel partnerships involve multiple rounds of demand communication and detail confirmation. The manufacturer's service response speed and communication efficiency are crucial. Consider whether the manufacturer responds to inquiries within 24 hours, whether a dedicated contact person is assigned (responsible for demand communication, progress feedback, and problem resolution), and whether they proactively provide professional advice (such as fabric substitutions and process optimization). Inefficient communication (such as delayed responses and frequent changes in contact personnel) often indicates potential information misalignment in subsequent collaborations. Therefore, prioritize manufacturers with professional and responsive services.

- Cooperation Flexibility and After-Sales Support: The needs of different partners vary, and the manufacturer's flexibility and after-sales support capabilities directly impact the cooperation experience. These include whether the manufacturer supports small-batch trial production (e.g., 30-50 pieces to reduce the risk of first-time collaboration), whether the process and plan can be adjusted based on demand (e.g., mid-production pattern modifications or fabric changes), and whether payment methods are flexible (e.g., prepayment ratio, final payment schedule). After-sales support must be clearly defined, including procedures for handling defective products (e.g., free reissues, payment deductions), pattern adjustment policies (e.g., whether modifications are available if the fit is not right), and after-sales response times (e.g., providing a solution within 48 hours of reporting an issue). Comprehensive after-sales service can reduce cooperation risks and protect the rights and interests of partners.

- Customer Reputation and Industry Qualifications: Verify the manufacturer's strength through customer reputation and industry qualifications. Check other customers' reviews on industry platforms (such as Alibaba and Global Sources), or ask the manufacturer for case studies and contact information (or directly inquire about past cooperation experiences). Also, pay attention to the manufacturer's industry qualifications, such as business licenses, clothing production licenses, ISO 9001 quality system certifications, and environmental certifications (such as OEKO-TEX® Standard 100, which certifies fabric safety and environmental protection). Manufacturers with formal qualifications are more trustworthy and can effectively avoid the risks of partnering with "shell companies" or "unqualified small workshops."

A practical validation approach for manufacturer screening

- Sample Verification: Request pre-production samples from the manufacturer (most high-quality manufacturers offer 1-3 free samples). Use the samples to evaluate fabric texture, craftsmanship, and fit. Only if the samples meet expectations can we proceed with further cooperation.

- Factory Inspection: For large orders (e.g., over 1,000 pieces), visit the manufacturer's factory to inspect the production environment, equipment, and quality control processes, gaining a direct understanding of their production capabilities. If an in-person inspection is not possible, request a video factory inspection, focusing on the production line and quality inspection process.

- Qualification Verification: Use the Enterprise Credit Information Publicity System to verify the manufacturer's business license, years of operation (manufacturers with more than 5 years of operation are generally more stable), and any records of default to ensure compliance and legality.

A breakdown of the entire process and key execution points for working with custom apparel manufacturers

- A clear collaboration process and key execution points are the core elements of "The Comprehensive Guide to Collaborating with a Custom Clothing Maker." This scientific process can reduce communication costs, mitigate collaboration risks, and ensure a smooth and manageable process from inception to implementation of custom clothing requests.

- Dongguan Siyinghong Garment has developed a "7-step standardized collaboration process" for custom clothing collaborations, with key execution points for each step to help partners efficiently advance their collaboration:

- Demand Communication and Proposal Confirmation: The partner submits their refined custom requirements (including design ideas, fabric preferences, order size, delivery time, etc.). The manufacturer then provides a preliminary proposal based on the requirements, including fabric recommendations (with fabric samples), process adaptation suggestions (e.g., digital direct printing for complex patterns, embroidery for logos), and a detailed quote (including fabric fees, labor costs, pattern making fees, and shipping costs). Key execution points: The partner must carefully verify the compatibility of the proposal with the requirements, especially the texture and color of the fabric samples, the feasibility of the process plan, and the transparency of the quote (no hidden fees). Any questions should be communicated promptly until both parties confirm the agreement.

- Design Optimization and File Output: If the partner has a preliminary design, the manufacturer can provide design optimization services (such as adjusting pattern proportions, matching Pantone colors, and optimizing pattern details). If the partner does not have a complete design, the manufacturer's design team can create design drawings (such as clothing style drawings and print pattern drawings) based on the partner's needs. The final output is standardized design files (such as AI vector graphics, PSD high-definition images, with dimensions and process requirements marked). Key points: The design files must be confirmed in writing by the partner (e.g., email or confirmation form) to ensure that design details are clear and unambiguous, to avoid production deviations due to non-standard design files.

- Pre-production Proofing and Sample Confirmation: The manufacturer will produce pre-production samples based on the confirmed plan and design documents (identical to the fabric, craftsmanship, and pattern used in mass production), annotating the sample information (such as fabric composition, dimensional parameters, and craftsmanship details). Upon receipt of the samples, the partner will inspect them based on four criteria: visual quality (design fidelity and color), tactile quality (fabric texture and craftsmanship), pattern (fitting or measuring), and quality (seam strength and print adhesion). Key points: If the sample requires modification (such as adjusting shoulder width or deepening print color), the manufacturer must provide clear modification suggestions (with specific parameters). The manufacturer will make modifications free of charge until the sample meets the quality standards. Both parties will then sign a "Sample Confirmation Form," clearly defining the sample as the quality standard for mass production.

- Contract Signing and Advance Payment: After sample confirmation, both parties will sign a formal cooperation contract, specifying the following details: order information (style, quantity, size ratio), price and payment method (e.g., 30%-50% advance payment, with the balance due before shipment or after receipt), delivery time and logistics methods, quality standards (based on confirmed samples), after-sales policy (defective product handling, compensation for delayed delivery), and liability for breach of contract. Key points: The contract should be carefully reviewed, especially clauses related to rights protection (e.g., handling of substandard quality, refundability of advance payments), to avoid ambiguous terms. It is recommended that advance payments be made through a public account, and payment receipts retained.

- Mass Production and Progress Tracking: After receiving the advance payment, the manufacturer will initiate mass production, following the process of "raw material procurement → fabric cutting → sewing and processing → craftsmanship (printing, embroidery, etc.) → semi-finished product inspection → finished product finishing." Key points: Partners can agree on a progress feedback mechanism with the manufacturer (e.g., synchronizing progress twice a week and providing photos/videos of key milestones such as cutting completion and craftsmanship completion). If any delays are detected, the reasons and solutions (e.g., whether batch delivery is necessary) should be communicated promptly to avoid impacting usage plans.

- Finished Product Inspection and Acceptance: After production is completed, the manufacturer will conduct a full inspection of the finished product (checking each piece's appearance, dimensions, workmanship, and quality, and eliminating defective products) and provide the partner with a "Finished Product Acceptance List" (including the actual production quantity, qualified quantity, and defective quantity). Partners can choose "Factory Acceptance" (in-person or by entrusting a third party to conduct an on-site inspection) or "Arrival Acceptance" (inspection within 3-7 days of receipt). Acceptance criteria are based on confirmed samples and the contract agreement. Key points: During acceptance, samples must be compared with the contract, focusing on quality consistency and quantity accuracy. If defective products exceed the agreed ratio, the manufacturer will be required to handle the situation according to the after-sales policy (such as free reissue or payment reduction).

- Final payment and logistics delivery: After acceptance, the partner pays the final payment as agreed in the contract. After receiving the final payment, the manufacturer will ship the goods according to the agreed logistics method (such as domestic express delivery, international sea freight/air freight) and provide a logistics tracking number. Implementation points: The logistics method should be selected according to the order size and timeliness requirements (express delivery for small orders, sea freight for large orders). For international orders, it is necessary to confirm whether the manufacturer can assist with customs declaration and clearance procedures to ensure smooth delivery of the goods.

Quality Control and Risk Avoidance Strategies in Custom Clothing Cooperation

When collaborating with custom clothing manufacturers, quality control and risk mitigation are crucial to ensuring a successful partnership and are crucial elements of "The Comprehensive Guide to Collaborating with a Custom Clothing Maker." Lack of effective quality control and risk mitigation measures can lead to substandard finished product quality, delivery delays, payment disputes, and other issues, resulting in losses.

Dongguan Siyinghong Garment has summarized four key quality control points and three risk mitigation strategies to help partners ensure quality control throughout the entire process and mitigate risks.

4 Key Quality Control Points for Custom Clothing Cooperation

1.Raw material source control: The quality of raw materials (fabrics and accessories) directly determines the quality of the finished product. Manufacturers must provide quality inspection reports for raw materials (such as fabric composition testing, color fastness testing, and accessory safety testing). Random raw material samples must be taken for verification (such as verifying that the fabric weight and color are consistent with the agreed-upon specifications, and checking the brand and quality of the accessories). For special fabrics (such as organic cotton or waterproof fabrics), manufacturers must provide corresponding certifications (such as organic cotton certification and waterproof grade testing reports) to avoid the use of inferior or substandard raw materials.

2.Control of Key Nodes in the Production Process: During key steps in mass production (cutting, sewing, and craftsmanship), manufacturers may be required to provide process photos or videos, or third parties may be commissioned to conduct inspections. Key control measures include:

-

- Cutting: Check for dimensional deviation (≤ 1cm) and consistency between the number of cut pieces and the order quantity to avoid subsequent sewing problems caused by cutting errors;

- Sewing: Check for thread density (≥ 8 stitches per 3cm), thread flatness (no skipped stitches, broken threads, or loose threads), and reinforcement of key areas (e.g., double-stitching of shoulders, cuffs, and pockets);

- Craftsmanship: Check for print/embroidery fidelity (color and detail consistent with the sample), firmness (no peeling after a tape test), and positional deviation (≤ 0.5cm) to ensure the expected finish.

3.Clearly define the standards for a complete inspection of finished products: Agree with the manufacturer in advance on specific standards for a complete inspection of finished products, including:

-

- Appearance inspection: No stains, loose threads, holes, or fabric defects; no missing, misprinted, or snagged prints/embroidery;

- Size inspection: Randomly sample 10%-15% of finished products and measure key dimensions (length, chest circumference, and shoulder width) with an error of ≤2cm (based on the confirmed sample size);

- Quality testing: Perform simple tests on finished products (e.g., a wash test: simulate daily washing 1-2 times to check for discoloration, pilling, and deformation; a tensile test: pull seams to check for strength) to ensure the durability of the finished product.

4.Sample-centric quality benchmark: Confirmed pre-production samples will serve as the quality benchmark throughout the entire collaboration process.