The Complete Guide to Customizing Your Under Armour Hoodies

If you're looking to create a high-quality, custom Under Armour sweatshirt as an eye-catching outfit for your team or company, this guide is tailor-made for you. It'll walk you through the key elements of the customization process, from the reasons to choose Under Armour, to various design customization options, professional design techniques, and the complete ordering process, breaking it down in detail.

We've partnered with countless teams and businesses in the streetwear world to create high-quality, Custom Apparel. Now, let's work together to create your very own Under Armour sweatshirt.

1. Why is Under Armour the preferred brand for Custom Apparel?

Choosing a brand to partner with for apparel is a crucial decision, and Under Armour stands out from the competition, making it the ideal choice for teams and businesses of all kinds. It's more than just a brand identity; it symbolizes an unwavering commitment to quality.

The reason for choosing Under Armour is mainly based on the following three core reasons:

● Top performance : Its fabric is designed for sports scenes and comfortable wearing, taking into account both functionality and experience.

● High-quality brand association : Pairing your brand logo with well-known and mature brands such as Under Armour can instantly enhance the visual quality of the logo.

● Super Durability : Under Armour hoodies are made of strong materials and have a long service life, so they can remain in good condition for a long time.

1. Excellent practicality and cutting-edge technology

Under Armour is known for its specialized performance fabrics. Among them, Armor Fleece® fabric offers lightweight, exceptional warmth, and the ability to move with the body. UA Storm technology provides breathability while making the fabric waterproof, elevating the wearing experience to a higher level.

Even in light rain, team members can stay dry; the fabric also has sweat-wicking function, so the wearer can always stay comfortable whether it is pre-game warm-up or corporate group activities.

2. High-end brand image

When your brand logo is printed on an Under Armour sweatshirt, your brand image will be instantly enhanced. In the sportswear market, Under Armour is a recognized mature and high-quality brand, and its "high quality, high performance" label is deeply rooted in people's hearts.

When people see your team or employees wearing customized Under Armour apparel, they will intuitively feel your emphasis on quality - this brand association can fully demonstrate your professionalism and pursuit of excellent quality.

3. Durable and suitable for long-term use

A custom sweatshirt isn't a one-time expense; it's a long-term investment, so durability is crucial. Under Armour sweatshirts are made with high-strength fabrics and seams that resist wear and tear, making them durable enough to withstand frequent wear and repeated washing.

Even after years of use, the custom patterns on the sweatshirts remain clear and bright. For teams and organizations, choosing high-quality custom Under Armour sweatshirts can maximize the value of every investment.

2. Choose the Right "Canvas": Recommended Under Armour Sweatshirt Models

Under Armour offers a wide variety of hoodies, and the key to choosing one is to choose one that suits your needs: sports teams may prefer functional hoodies, while companies may prefer simple fleece styles as gifts.

To help you make the right choice, we've compiled comparison information for several popular models. You can also browse the "Custom Under Armour Sweatshirts and Hoodies Collection" for more style inspiration.

| Model Name | Core Features | Applicable Scenarios | Customization Considerations |

| UA Hustle Fleece Hoodie | Armour Fleece® fabric with soft interior and front pockets | Team apparel, fan apparel, campus groups | Suitable for screen printing and embroidery, highly versatile |

| UA Rival Fleece Hoodie | Cotton-blend fleece with a raised inner layer for warmth and classic style | Corporate gifts, daily wear, employee uniforms | Fleece surface is smooth and suitable for fine embroidery |

| UA Storm Armor Fleece Hoodie | UA Storm waterproof coating, breathable and lightweight | Outdoor activities, coaching clothing, all-weather team wear | Embroidery works best, screen printing requires special ink and waterproof coating |

| UA Double Threat Armor Fleece | Loose fit, moisture-wicking, quick-drying fabric | Sports teams, training wear, high-performance demand scenarios | For screen printing, it is recommended to use elastic ink to maintain the ductility of the fabric, and embroidery is suitable for logos. |

3. Customization Method Showdown: Embroidery vs. Screen Printing

After choosing your sweatshirt, the next step is to decide on a custom method. Embroidery and screen printing are two popular techniques, each with its own advantages and disadvantages when applied to Under Armour's functional fabrics.

Understanding the characteristics of the two methods can help you make a more cost-effective choice - the key to the success of customizing Under Armour hoodies lies in perfectly matching design technology with fabric characteristics.

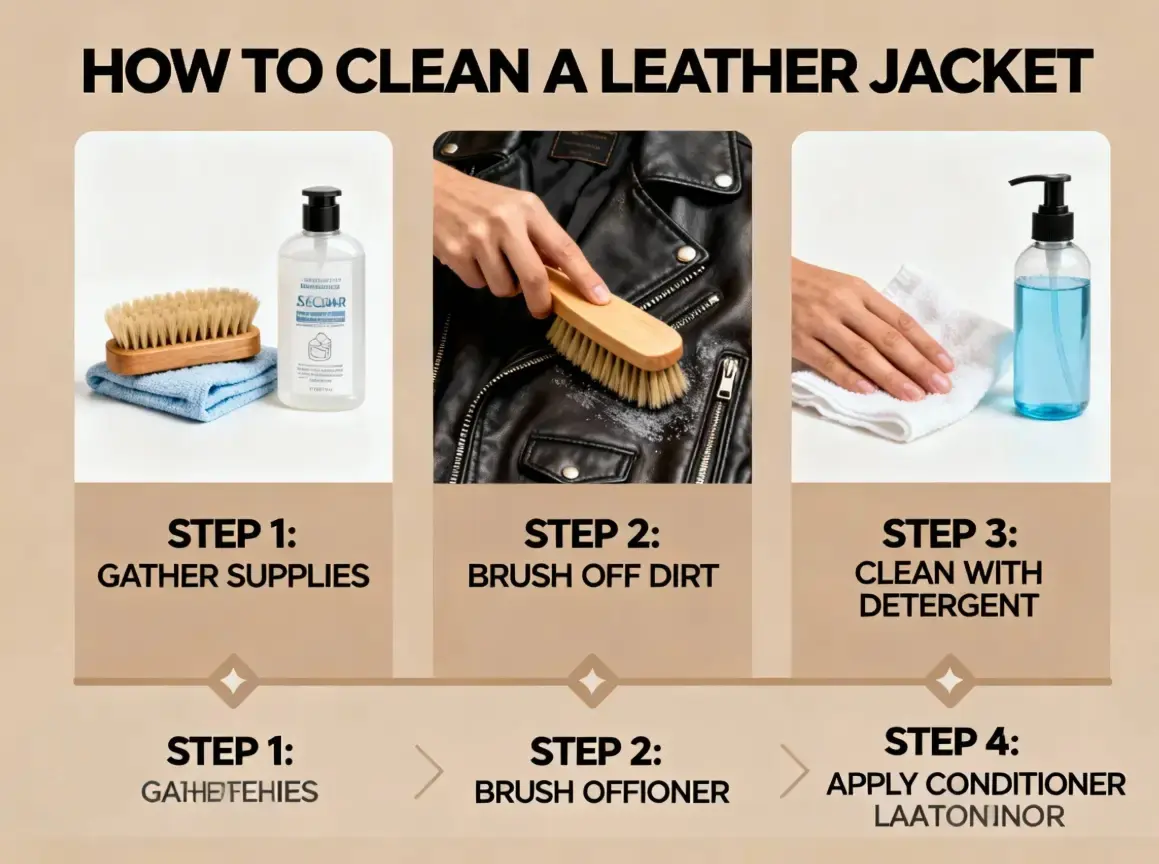

1. What is embroidery?

Embroidery requires the use of a sewing machine and specialized techniques, stitching patterns onto the surface of clothing with thread, creating a three-dimensional texture. This method offers exceptional durability and a high-end, professional feel, making it particularly suitable for printing logos on thicker fabrics like fleece. The resulting pattern is rich and timeless, perfectly complementing your brand's style.

2. What is screen printing?

Screen printing is a process whereby ink is applied to the sweatshirt through a mesh screen. A separate screen is produced for each color in the design. This method is suitable for producing large, multi-colored, complex designs, resulting in a soft, smooth finish.

For Under Armour's functional fabrics, we use special ink to ensure that the ink can stretch with the fabric and remain breathable, making the sweatshirt comfortable without losing practical functions.

3. Horizontal comparison table

The following table provides a quick overview of the differences between the two methods:

| Comparison Dimension | embroidery | Screen printing |

| Applicable design | Logos, names, small-size designs, and graphics that seek a professional feel | Large-scale graphics, multi-color designs, team names/numbers |

| Durability | Extremely durable, the seams last as long as the garment | More durable, may fade or crack after many years of washing |

| Cost Calculation | Charged by the number of stitches, small logo, high cost performance | Charged by color quantity, large orders have lower unit price |

| Look and feel | Three-dimensional texture, high-end texture | Smooth and soft to the touch |

| Fabric adaptability | Suitable for fleece, heavy cotton fabrics, thin technical fabrics need a backing | Suitable for most fabrics, high-performance polyester fibers require special ink |

4. Professional recommendations

● If you’re looking for a high-end, professional look, such as a corporate logo on a fleece sweatshirt like the UA Rival, embroidery is the preferred choice – it creates a classic and durable design that perfectly conveys your brand image.

● If you are purchasing a large order for a sports team and need to print a large, eye-catching pattern, and the sweatshirt is lightweight, we recommend screen printing - this can ensure the pattern effect while keeping the clothing light and suitable for athletes to wear.

4. Creating the Perfect Custom Sweatshirt: Professional Design Tips

A quality product begins with a great design. As experts in custom clothing, we understand the ins and outs of design. Follow these simple rules to avoid common mistakes and ensure your custom sweatshirts look professional.

1. Start with high-quality design documents

The quality of the design file directly affects the final effect, so be sure to use high-definition files:

● Vector files (such as AI and EPS formats) are most suitable for logo design and can be scaled without losing quality.

● If bitmap files (such as JPEG and PNG formats) are used, the size must be large enough;

● Generally speaking, vector files produce clearer and sharper prints or embroidery.

2. Focus on color and contrast

Choose a thread or ink color that contrasts sharply with the base color of the sweatshirt:

● Avoid printing dark logos on similar-colored sweatshirts (e.g., a dark blue logo on a navy blue sweatshirt), as this combination has low visual recognition.

● A white or silver logo paired with a dark sweatshirt creates a strong contrast, making the pattern more eye-catching;

● It is recommended to confirm the color by comparing it with the official Under Armour fabric color card (such as "Carbon Heather" and "Royal Blue") to ensure that the design effect is consistent with your expectations.

3. The position of the pattern determines the visual effect

The choice of pattern location is crucial:

● Conventional locations such as the left chest, front body, and sleeves have become classic choices due to their visual balance and easy identification;

● Avoid printing fine patterns on uneven areas such as seams, zippers, and pocket edges, as these areas can easily cause pattern deformation.

● You can refer to "Under Armour Custom Sweatshirt Design Case" for more position design inspiration.

4. Embroidery patterns need to be simplified

Embroidery techniques can't produce extremely fine details or smooth color gradients. Small text or complex lines can become blurred by the stitching. If your logo is complex, simplify it before embroidery. Removing small elements or using a solid color will create a cleaner, more impactful embroidery effect.

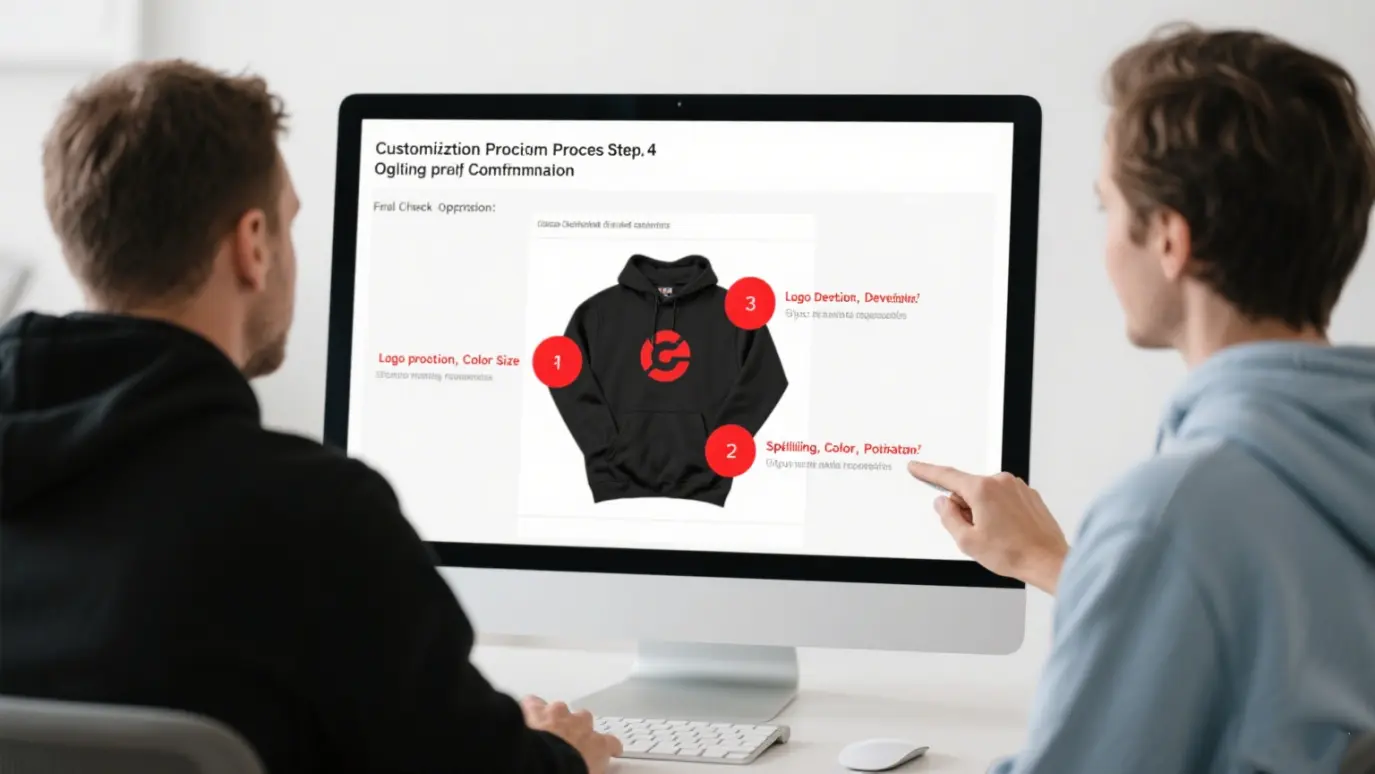

5. Be sure to confirm the digital proof

Before you start production, be sure to request a digital proof (a simulated image of the final product). This is your final chance to check before production begins, carefully checking for typos, color deviations, and pattern placement. Only after you confirm everything is correct can you start production and ensure the final product is exactly as you intended.

5. Step-by-step process of working with professional Manufacturers

Customizing clothing may seem complex, but once you break it down, the steps are clear. Working with a dedicated team makes the entire process smooth and worry-free. Here's the complete process from creative conception to finished product delivery:

1.Determine the design and sweatshirt model : Combine the previous tips to select your desired sweatshirt model, customization method, and final design.

2.Count quantity and size : Accurately counting the quantity of each size required is the key basis for obtaining an accurate quotation.

3.Choose a professional customization partner : Professional custom sweatshirt Manufacturers will provide you with guidance throughout the process, help the project proceed smoothly, and ensure that the customization effect meets the standards.

4.Submit design files and get a quote : Send high-definition design files to partners along with details like sweatshirt model, order quantity, customization method, etc., to get a detailed quote.

5.Review and confirm the digital sample : After receiving the digital sample, carefully check every detail, sign and confirm after confirming that it is correct, and the manufacturer will then start production.

6.Production and quality testing : Manufacturers start production according to orders, and each sweatshirt will undergo strict quality testing to ensure that it meets high quality standards.

7.Receive customized sweatshirts : After production is completed, the order will be arranged for shipment, and you will finally receive a professional customized Under Armour sweatshirt that can be worn directly.

6. Customized sweatshirt maintenance guide: extending service life

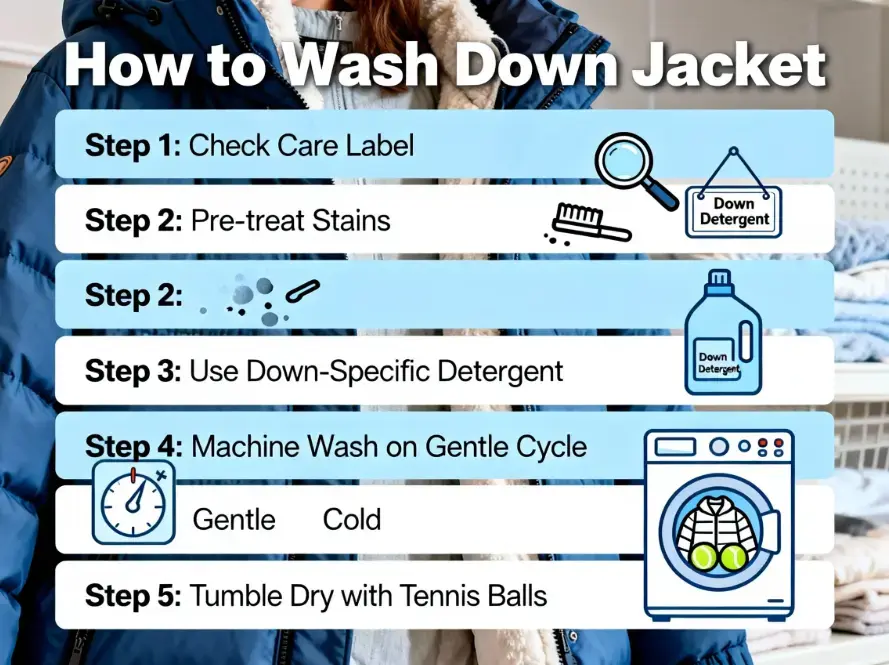

Since you've invested in a high-quality custom Under Armour sweatshirt, you need to take good care of it to keep the clothing and custom patterns in good condition for a long time. Please follow these maintenance tips:

● Recommended steps : Turn the sweatshirt inside out before washing to avoid damage to the embroidery or print from rubbing against other clothing; wash on a gentle cycle in cold water to prevent damage to the high-performance fabric and fading of the ink; tumble dry on low heat or hang to dry to avoid shrinkage or fabric aging caused by high temperatures.

● Don'ts : Do not use fabric softener, as it will clog the breathable pores of high-performance fabrics and reduce moisture absorption and perspiration function; do not directly iron custom patterns, as the high temperature will melt the screen printing ink and embroidery thread, affecting the design effect.

7. Frequently Asked Questions about Customized Under Armour Sweatshirts

1. What is the minimum order quantity for custom Under Armour sweatshirts?

Minimum order quantities vary by supplier: some specialize in bulk orders for teams and businesses and offer more favorable unit prices; others support single-piece customization. We recommend consulting with the supplier for details based on your specific project needs.

2. How long does the customization process take?

Normally, it takes 2-3 weeks from digital sample confirmation to finished product delivery. However, order complexity, quantity, and manufacturer schedules can affect lead times. If you have urgent needs, please inquire about expedited service.

3. Can I bring my own Under Armour sweatshirt for customization?

Most professional customizers (the content of this document is not fully described here, and specific details need to be communicated and confirmed with the customizer).

4. How much does it cost to customize an Under Armour sweatshirt?

Costs are primarily influenced by three factors: the specific model of hoodie chosen (different models have different base pricing); the method of customization (embroidery is charged by the number of stitches, screen printing by the number of colors); and the total order volume (the larger the order volume, the lower the unit cost generally).

5. Will customization affect the performance of the sweatshirt?

Professional customization will not affect the performance of the sweatshirt: a special substrate will be used during embroidery to ensure the stability of the fabric without destroying its touch and function; screen printing will use special ink suitable for high-performance fabrics to ensure that the fabric maintains ductility and breathability.