How to Make Custom T Shirts

Introduction

T shirts are a wardrobe essential for people of all ages and styles—and more and more individuals, brands, and teams are asking “how to make custom t shirts” to break free from generic mass-produced options. Custom t shirts let you showcase personal flair, brand logos, team spirit, or event themes, turning a simple garment into a unique statement piece. Whether you’re crafting one-off tees for personal wear, bulk orders for brand merchandise, or uniforms for a team, the process involves careful decisions from fabric selection to design execution. Dongguan Siyinghong Garment, with over a decade of apparel customization experience and professional production technology, offers a step-by-step guide to making custom t shirts. Below, we’ll break down every key stage—from defining your goals to final delivery—helping you turn creative ideas into high-quality, wearable custom tees.

Clarify Your Custom T Shirt Goals & Core Requirements

The first answer to “how to make custom t shirts” is to define your goals and core needs—this ensures the final product aligns with its purpose and your expectations. Start by answering these key questions to narrow down your direction:

Key Elements to Outline:

- Purpose & Audience: Are the custom t shirts for personal daily wear, brand retail, corporate uniforms, sports team gear, or event giveaways (e.g., music festivals, charity runs)? The audience (age, gender, lifestyle) will shape fit, style, and design.

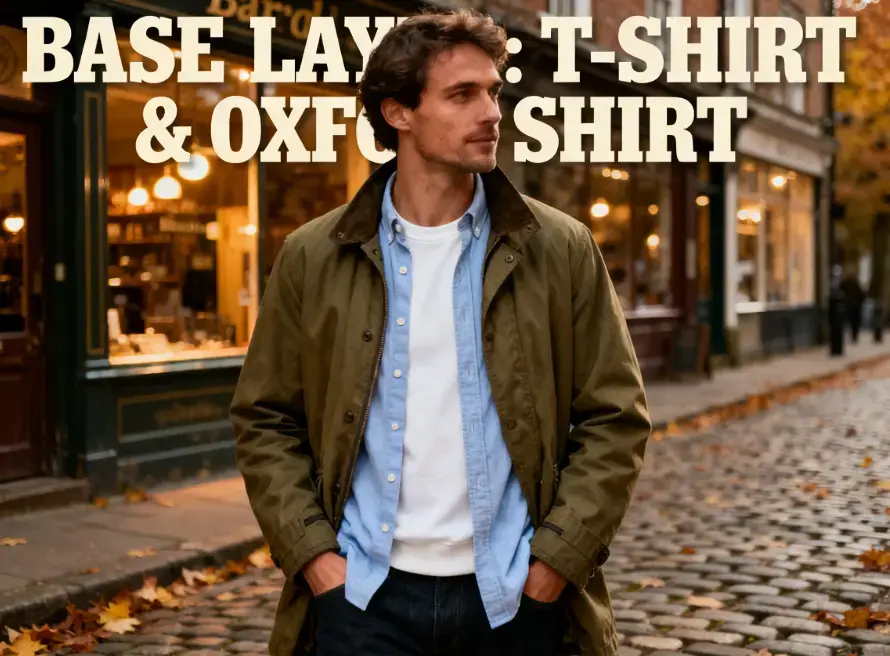

- Style Orientation: Choose a base t shirt style—options include classic crew neck, V-neck, scoop neck, long sleeve, short sleeve, oversized, or cropped. Consider the season (e.g., long sleeve for autumn/winter) and wearing scenario (e.g., cropped for fashion-forward brands).

- Fit Preference: Decide on the fit—slim (tailored for a sleek look), regular (versatile for most body types), relaxed (casual and roomy), or oversized (trendy for streetwear). For bulk orders, plan size ranges (XS-5XL) to cover diverse needs.

- Design Focal Points: Identify the star elements of your custom t shirt—brand logos, original patterns, text (slogans, team names, event dates), or decorative accents (e.g., contrast stitching, small patches).

- Color Scheme: Pick a base color for the t shirt (solid, heathered, tie-dyed) and coordinate accent colors for designs (e.g., white logo on black tees, neon text on light gray tees). Use Pantone color codes for consistency if branding is involved.

Dongguan Siyinghong Garment’s team can help refine your requirements—for example, suggesting oversized styles for youth brands or moisture-wicking fabrics for sports teams—ensuring your custom t shirts are both stylish and functional.

Choose the Right Fabric for Custom T Shirts

The comfort, durability, and look of custom t shirts start with fabric—this is a make-or-break step in “how to make custom t shirts.” The right fabric not only affects wearability but also how well your design (print, embroidery) adheres and lasts. Here’s how to select fabric based on your needs:

Common Fabric Options for Custom T Shirts

- 100% Combed Cotton: The gold standard for comfort—soft, breathable, and skin-friendly, with minimal pilling after washing. Ideal for daily wear, brand merchandise, or casual uniforms. It works well with all customization techniques (embroidery, printing) and supports treatments like pre-shrinking to avoid size changes.

- Cotton-Polyester Blend: A mix of cotton (for comfort) and polyester (for durability and wrinkle resistance)—common ratios include 65% polyester + 35% cotton or 50/50. Perfect for bulk orders (e.g., team uniforms, event giveaways) as it’s affordable, easy to care for, and retains its shape well.

- Organic Cotton: GOTS-certified (Global Organic Textile Standard), grown without pesticides or harmful chemicals. Eco-friendly and hypoallergenic, making it a top choice for sustainable brands, health-conscious individuals, or baby/kid’s custom t shirts.

- Modal: Made from natural beech wood pulp—ultra-soft, lightweight, and has excellent drape. It’s breathable and moisture-wicking, suitable for high-end casual tees or summer styles.

- Linen-Cotton Blend: Combines linen’s breathability (ideal for hot weather) with cotton’s softness. It has a natural, relaxed texture, perfect for vacation-themed custom t shirts or bohemian-style brands.

- Performance Fabrics (Polyester-Spandex): Moisture-wicking, quick-drying, and stretchy—designed for sports or activewear. Great for gym teams, running clubs, or outdoor event tees, as it keeps wearers cool and comfortable during activity.

Fabric Weight Guide

Fabric weight (measured in grams per square meter, gsm) affects thickness and durability:

- Lightweight (130-150 gsm): Thin and breathable, suitable for summer or layering (e.g., undershirts, summer event tees).

- Midweight (160-190 gsm): The most versatile—balances comfort and durability, ideal for year-round wear and most custom t shirt needs (brand tees, uniforms).

- Heavyweight (200+ gsm): Thick and sturdy, with a premium feel. Suitable for winter layering, workwear, or long-lasting brand merchandise (e.g., vintage-inspired tees).

Dongguan Siyinghong Garment provides free fabric samples, so you can feel texture, test color, and confirm quality before moving to production.

Select Customization Techniques to Bring Your Design to Life

Once you’ve chosen the fabric and base style, the next critical step in “how to make custom t shirts” is picking the right customization technique. The method you select depends on your design complexity, budget, order quantity, and desired durability—here are the most popular options:

Embroidery

Ideal for logos, small patterns, or text that needs a premium, textured finish. Embroidery is durable (resists washing and fading) and works best on thicker fabrics (midweight to heavyweight cotton). Options include:

- Flat Embroidery: Smooth and precise, perfect for detailed logos (e.g., corporate emblems) or fine text (e.g., team names on chests).

- 3D Embroidery: Adds depth and dimension, making logos stand out (great for brand merchandise or team tees that need visibility).

- Contrast Embroidery: Uses thread colors that pop against the t shirt fabric (e.g., black thread on white tees, red thread on navy tees) to draw attention to key designs.

Printing

The most versatile option for bold, colorful, or large-scale designs—here are the top printing methods for custom t shirts:

- Screen Printing: Best for simple, solid-color designs (e.g., logos, slogans) and bulk orders (100+ pieces). It’s cost-effective, has excellent color fastness, and works on most fabrics. Note: It’s less ideal for complex, multi-color designs (each color requires a separate screen).

- Digital Direct Printing (DTG): Perfect for intricate, full-color designs (e.g., photos, detailed illustrations, gradient patterns). It prints directly onto the fabric, capturing fine details, and works well on light-colored tees (for vibrant results) or dark tees (with a white underbase). Great for small-batch orders or one-off custom tees.

- Heat Transfer: Quick and flexible for small orders or temporary designs (e.g., limited-edition event tees). It uses a printed transfer sheet applied with heat—ideal for last-minute customizations, but durability is lower than embroidery or screen printing (may fade after multiple washes).

- Sublimation Printing: Best for all-over prints or designs that cover the entire t shirt (e.g., tie-dye effects, full-front graphics). It works on polyester or polyester-blend fabrics, as the ink bonds with the fabric fibers—resulting in bright, long-lasting colors that don’t peel.

Additional Customization Details

Elevate your custom t shirts with small but impactful details:

- Tag Customization: Replace generic Brand Tags with your own woven or printed tags (featuring your brand name, size, or care instructions) for a premium look.

- Neck Tape: Add a colored or branded neck tape (inside the neckline) to prevent irritation and enhance durability—common in high-end custom tees.

- Contrast Stitching: Use colored thread for seams (e.g., white stitching on black tees) to add subtle style without overwhelming the design.

- Pocket Prints/Embroidery: Add a small design (logo, symbol) to a chest pocket for a minimalist, sophisticated look.

Dongguan Siyinghong Garment’s craftsmen can recommend the best technique for your project—for example, screen printing for 500+ team tees or DTG for a one-off photo-based custom tee.

Finalize Design & Submit Files

To ensure your custom t shirts turn out as expected, precise design finalization is key to “how to make custom t shirts.” Follow these steps to avoid errors and ensure clarity:

Prepare High-Quality Design Files

- File Formats: Submit vector files (AI, EPS, SVG) for logos or text—these scale without losing quality. For photos or illustrations, use high-resolution raster files (PNG, JPG) with a minimum of 300 DPI (dots per inch).

- Design Size & Placement: Specify the size of your design (e.g., 10x12 inches for a full-front print) and placement (e.g., center chest, left chest, back yoke). Use a t shirt template (provided by the manufacturer) to mark positions—this avoids misalignment in production.

- Color Confirmation: Provide Pantone color codes for your design and t shirt base—this ensures consistency across all pieces, especially for brand or team orders where color accuracy matters.

Review a Digital Mockup

Most Manufacturers (including Dongguan Siyinghong Garment) will send a digital mockup of your custom t shirt—this is a 2D or 3D rendering that shows how the design will look on the actual tee. Take time to:

- Check if the design size and placement are correct.

- Verify that colors match your expectations (e.g., does the logo blue match your brand’s Pantone code?).

- Ensure text is legible (especially small fonts) and patterns are aligned properly.

Request revisions if needed—this step prevents costly mistakes during production.

Collaborate with a Professional Manufacturer for Sampling

For high-quality, consistent custom t shirts, working with a professional manufacturer is non-negotiable in “how to make custom t shirts”—especially for bulk orders or complex designs. The sampling process lets you test the final product before mass production:

Submit Your Requirements

Share your finalized design files, fabric choice, base style, and size requirements with the manufacturer. Dongguan Siyinghong Garment offers one-on-one communication to clarify details like:

- Embroidery thread color (if using embroidery).

- Print type (e.g., DTG vs. screen printing) and finish (matte vs. glossy).

- Size specifications (e.g., “oversized fit—2 inches longer in the body”).

Review the Physical Sample

The manufacturer will produce 1-3 physical samples (typically taking 3-5 working days) for your review. When testing the sample, check:

- Fit: Try on the sample (or have a model wear it) to confirm the fit matches your expectations (e.g., is the oversized tee roomy enough? Is the slim fit not too tight?).

- Fabric Quality: Feel the fabric—does it match the sample you tested earlier? Is it soft, breathable, or durable as needed?

- Design Execution: Inspect the embroidery/print—Is the logo crisp? Are colors accurate? Is the stitching neat (for embroidery)?

- Durability: Do a quick wash test (if possible) to check for fading, peeling, or shrinking (critical for long-lasting custom tees).

Request Revisions

If adjustments are needed—e.g., “make the logo 1 inch smaller,” “change the thread color from red to burgundy,” “adjust the sleeve length by 0.5 inches”—communicate clearly with the manufacturer. Dongguan Siyinghong Garment offers free sample revisions to ensure every detail is perfect before moving to mass production.

Confirm Production & Ensure Quality Control

Once the sample is approved, the final step in “how to make custom t shirts” is to lock in production details and ensure strict quality control—this guarantees every tee in your order meets the same high standard as the sample.

Finalize Production Details

- Order Quantity: Confirm the number of tees per size (e.g., 50 XS, 100 S, 150 M) to avoid shortages or excess.

- Delivery Timeline: Agree on a production schedule—most manufacturers take 7-12 working days for bulk orders (50-500 pieces), plus shipping time. Ask for expedited services if you need tees for a specific event.

- Packaging: Choose packaging that aligns with your needs—e.g., individual polybags (for protection), custom brand boxes (for retail), or bulk packaging (for team orders). Add custom tags or stickers for a branded touch.

Quality Control Checks

Professional manufacturers like Dongguan Siyinghong Garment implement multi-stage inspections to avoid defects:

- Fabric Inspection: Before cutting, check for holes, color inconsistencies, or texture flaws in the fabric.

- Production Inspection: Randomly check tees during production to ensure designs are applied correctly, stitching is neat, and sizes are consistent.

- Finished Product Inspection: After production, inspect every tee for fit, design accuracy, and defects (e.g., loose threads, misprinted logos).

- Wash Testing: For a small batch of tees, test washing and drying to confirm no fading, shrinking, or peeling.

Delivery & After-Sales Support

Once production is complete, the manufacturer will arrange shipping—supporting global delivery via DHL, FedEx, or sea freight (for large orders). You’ll receive a tracking number to monitor the shipment. Dongguan Siyinghong Garment also offers after-sales support: if any tees arrive with defects, we’ll replace them or offer a solution to ensure your satisfaction.

Conclusion

Now you have a complete, actionable guide to “how to make custom t shirts”—from defining your goals and choosing fabric to finalizing production. Every step, from design to delivery, plays a role in creating custom tees that are stylish, comfortable, and aligned with your needs. Whether you’re making one tee for yourself, 100 for a team, or 1000 for a brand, Dongguan Siyinghong Garment’s professional customization services, flexible options, and strict quality control ensure your vision becomes a reality. With our expertise, you can turn simple t shirts into unique pieces that showcase personality, build brand loyalty, or unite a team.

FAQ

FAQ 1: What’s the best fabric for custom t shirts?

It depends on your needs: 100% combed cotton for comfort (daily wear/brand tees), cotton-polyester blends for affordability (bulk orders), organic cotton for sustainability, and performance fabrics for sports/activewear. We can recommend the right option based on your project.

FAQ 2: Can I make a custom t shirt with my own photo or illustration?

Yes! Use Digital Direct Printing (DTG) for photos or intricate illustrations—DTG captures fine details and full colors accurately. We accept high-resolution PNG/JPG files (300 DPI+) and can help optimize your design for printing.

FAQ 3: Is there a minimum order quantity (MOQ) for custom t shirts?

No—Dongguan Siyinghong Garment supports one-off custom tees (for personal wear) and bulk orders (1000+ for brands). We maintain the same quality standards regardless of quantity.

FAQ 4: How long does it take to make custom t shirts?

Lead time varies by order size and complexity: 3-5 working days for a sample, 7-12 working days for bulk production (50-500 pieces), plus shipping. Expedited services are available for urgent orders (e.g., 5 working days for 100 tees).