How to Identify and Select Clothing Wholesale Suppliers – Dongguan Siyinghong Garment

Today, offline clothing store owners, e-commerce sellers, and startup clothing brands alike are considering "How to Identify and Select Clothing Wholesale Suppliers," hoping to find partners with a stable supply, high-quality products, and reasonable prices. Compared to retail purchases, professional clothing wholesale suppliers not only offer a rich selection of products but also support bulk price negotiation, flexible replenishment, and even custom styles, helping merchants reduce costs and improve competitiveness.

Dongguan Siyinghong Garment, a supplier with 15 years of experience in the clothing wholesale sector, has provided wholesale services across a full range of categories, including casual wear, business wear, and sportswear, to over 600 clients worldwide. They are deeply familiar with the procurement needs and selection pain points of different merchants. Below, we will systematically explain "How to Identify and Select Clothing Wholesale Suppliers" from the perspectives of supplier identification, selection criteria, docking processes, category adaptation, and risk mitigation, helping you effectively identify suitable partners.

How to accurately identify reliable wholesale clothing suppliers?

When searching for "How to Identify and Select Clothing Wholesale Suppliers," "accurately identifying reliable suppliers" is the first step and the key to avoiding future disputes. Many merchants mistakenly choose "middlemen" or "small workshop-style suppliers," facing problems such as inconsistent quality, out-of-stock, and lack of after-sales service.

To identify reliable clothing wholesale suppliers, there are three core paths and verification methods:

- Screen potential suppliers through formal channels: Prioritize obtaining supplier resources from industry-specific platforms, trade shows, and word-of-mouth recommendations, avoiding blindly searching on informal websites.

- Industry platforms: Such as Alibaba International Station and Global Sources. Select suppliers marked "Qualified Merchants" and "In-depth Factory Inspection." These platforms will verify supplier qualifications and reduce cooperation risks.

- Offline exhibitions: Participate in professional exhibitions such as the China Fashion and Accessories Expo and the Guangzhou Baima Fashion Fair to personally inspect suppliers' sample quality and production capabilities, while also obtaining the latest styles.

- Word-of-mouth recommendations: Consult with peers in the same industry for high-quality suppliers you have worked with, or review genuine reviews from other suppliers through industry communities and forums. Prioritize suppliers with a long-term track record of cooperation.

2.Verify the supplier's core qualifications and capabilities: Eliminate "shell companies" or "middlemen" through qualification verification and on-site inspections to confirm the supplier's true capabilities.

-

- Qualification Verification: Require the supplier to provide a business license, clothing production license (if the factory is self-owned), and import and export rights certificate (if wholesale is required). Check the company's operating history and any records of default through the Enterprise Credit Information Publicity System. Suppliers with more than five years of operation and no record of bad faith are considered more reliable.

- Capability Verification: Inquire whether the supplier owns its own factory. You can request a video of the factory or conduct a video inspection, focusing on the production workshop, storage capacity, and quality inspection procedures. Self-owned factories can better control quality and delivery time.

- Sample Testing: Request samples of target product categories (e.g., women's dresses, men's sweatshirts) to test fabric texture, sewing craftsmanship, and color fastness (for color fading after washing). Sample quality is a direct reflection of the supplier's capabilities.

3.Evaluate the supplier's service responsiveness and cooperation sincerity: Reliable suppliers will demonstrate a professional service attitude and transparent cooperation mechanisms in the early stages of the partnership.

-

- Response Speed: If a supplier responds within 24 hours after inquiring about your needs and provides a detailed product catalog and quotation, they demonstrate high service efficiency.

- Information Transparency: Proactively inform suppliers of minimum order quantities, lead times, payment methods, and after-sales policies, avoiding vague statements (such as "price negotiable" without providing a rough range) to avoid hidden costs later.

- Flexibility: Whether small trial orders (e.g., 50-100 pieces) are supported, and whether styles and sizes can be adjusted based on demand. Flexible partnership models are more suitable for startups or trial sales.

Core screening dimensions and evaluation methods for wholesale clothing suppliers

Clarifying your screening criteria is key to identifying and selecting clothing wholesale suppliers. Starting from your own needs, you should comprehensively evaluate suppliers' products, prices, services, and capabilities. Avoid focusing solely on a single factor (such as low price) and potentially leading to partnership risks.

Dongguan Siyinghong Garment has summarized five core screening criteria and corresponding evaluation methods to help you thoroughly evaluate suppliers:

Product quality and category compatibility

- Evaluation method:

a. Check the sample's fabric composition (e.g., if it's labeled 100% cotton, this can be easily verified by burning; pure cotton produces grayish-white ash with no hard lumps), sewing workmanship (sewing density: ≥8 stitches per 3cm, no skipped or broken threads), and dimensional deviation (randomly measure three samples; a deviation of ≤2cm is acceptable).

b. Verify the supplier's product category coverage. For example, if a retailer specializes in trendy sweatshirts, it's best to prioritize suppliers that specialize in "casual wear wholesale" over "all-category miscellaneous wholesale." The higher the category focus, the more specialized the product.

c. Investigate the supplier's style update rate (e.g., whether they release 20-30 new products per month) and whether they can keep up with market trends (e.g., seasonally popular colors and styles) to avoid overstocking due to outdated styles.

Price competitiveness and profit margins

- Evaluation Focus: Is the supplier's wholesale price reasonable? Does it leave sufficient profit margin for merchants? Is there a transparent pricing mechanism?

- Evaluation Method:

a. Compare quotes from 3-5 suppliers of similar quality to avoid "low-price traps" (e.g., quotes far below the market average indicate quality issues). High-quality suppliers should offer prices within a reasonable market range and provide detailed price structure (fabric, labor, and shipping costs).

b. Inquire about whether there is a "tiered pricing policy," such as a 5% price reduction for orders over 500 pieces and an 8% price reduction for orders over 1,000 pieces. Tiered pricing can help merchants reduce long-term procurement costs.

c. Confirm any hidden costs, such as minimum order quantity requirements (whether there is a surcharge for orders below the minimum order quantity), shipping fee coverage (whether shipping is free, logistics premiums), and customization fees (e.g., whether there are additional charges for logo printing or size changes).

Delivery capability and inventory stability

- Evaluation Focus: Whether the supplier can deliver on time and whether inventory is sufficient to avoid sales impacted by stock-outs.

- Evaluation Methods:

a. Identify the supplier's standard delivery cycle (e.g., 3-5 days for spot orders, 10-15 days for custom orders) and inquire about their response time for urgent orders (e.g., whether they can expedite delivery within 3 days, and how the expedited delivery fee is calculated).

b. Understand the supplier's inventory management practices, including whether they have regular inventory (e.g., ≥500 items of regular styles), and whether they offer real-time inventory tracking to avoid being told "out of stock" after placing an order.

c. Review past customer delivery reviews to determine whether they frequently experience delayed delivery and whether they offer reasonable compensation for delays (e.g., payment reduction, free reshipment).

After-sales guarantee and cooperation support

- Evaluation Focus: Whether the supplier can properly handle defective and slow-moving products, and whether it provides additional support (such as returns, exchanges, restocking, and design suggestions).

- Evaluation Methodology:

a. Confirm the after-sales policy. For example, if the defective rate is ≤3%, free reshipment is available. Slow-moving products can be exchanged for a similar product within 15 days of receipt (without affecting resale). After-sales terms must be clearly stated in the contract.

b. Inquire about restocking support, such as whether subsequent restocking can maintain the same quality as the initial order, and whether the restocking cycle is shortened (e.g., 5 days for a regular order, 3 days for a restocking).

c. Inquire about whether additional services are provided, such as providing e-commerce sellers with product images and detail page copywriting, and providing brand owners with style and design optimization suggestions. Additional services can improve the cost-effectiveness of the partnership.

Supply chain stability and risk resistance

- Evaluation Focus: Whether the supplier can cope with market fluctuations (such as fabric price increases or logistics outages) and ensure long-term stability.

- Evaluation Methodology:

a. Inquire about the supplier's fabric sourcing channels and whether they have long-term, high-quality fabric suppliers (e.g., three or more stable suppliers) to avoid production halts due to stockouts at a single supplier.

b. Understand their emergency response plans, such as whether they can switch to alternative logistics channels in the event of a logistics outage, and whether they negotiate price adjustments with merchants in advance when fabric prices increase, rather than unilaterally increasing them.

c. Examine the supplier's production flexibility, such as whether they can increase production capacity during peak seasons (e.g., Singles' Day and Christmas) to meet merchants' bulk replenishment needs and avoid stockouts during peak seasons.

The practical process of connecting online and offline clothing wholesale suppliers

A clear matching process can improve screening efficiency and reduce communication costs, which is also the core content of "How to Identify and Select Clothing Wholesale Suppliers". Whether it is online or offline matching, it is necessary to follow a standardized process to ensure that each step has a clear goal and verification link.

Online docking process (suitable for remote collaboration and preliminary screening)

- Communicate your needs and request information: Use the supplier's official website form, email, or online customer service to clearly define your requirements (e.g., category: women's jeans, order quantity: 200 pieces, delivery time: 10 days). Request a product catalog, quotation, and certifications (business license, factory photos) from the supplier to initially determine if they are a good match.

- Sample Confirmation and Quality Testing: Select two or three target products and pay the sample fee (most suppliers can deduct this fee from future bulk orders). Upon receiving the samples, test them according to the quality assessment methods mentioned above to confirm that the fabric, craftsmanship, and dimensions meet your requirements. If they do not meet the requirements, eliminate the supplier; if they do, proceed to the next step.

- Negotiate Details and Sign Contract: Confirm the details of the cooperation with the supplier, including the final quote, minimum order quantity, payment method (e.g., 30% down payment, 70% balance due before shipment), delivery time, and after-sales policy. All details should be clearly stated in the formal contract to avoid verbal agreements. Also, ask the supplier to provide a production plan (e.g., 3 days for fabric procurement, 5 days for production, and 2 days for logistics) to ensure a manageable lead time.

- Small-batch trial orders and effect verification: For the first cooperation, it is recommended to place a small-batch trial order (such as 50-100 pieces). During the trial order, observe the supplier's production progress feedback (such as synchronizing progress once a day), delivery punctuality, and the consistency of finished product quality with the sample. After the trial order is successful, the scale of cooperation can be gradually expanded.

Offline docking process (suitable for large-scale cooperation and in-depth investigation)

- Exhibition/Factory Inspection and Preliminary Negotiation: Attend a clothing exhibition or visit a supplier's factory to inspect sample quality, production equipment, and storage capacity. Discuss requirements face-to-face with the responsible person (e.g., customized styles, bulk purchase pricing), assess the supplier's capabilities, and initially shortlist 2-3 potential partners.

- Sample Customization and Detail Confirmation: Specific sample requirements (e.g., specifying fabrics, adjusting style details), and requesting the production of custom samples from potential suppliers. After sample confirmation, negotiate details such as price, minimum order quantity, and delivery time to clarify the responsibilities of both parties.

- Contract Signing and Advance Payment: Sign a formal contract, highlighting quality standards, delivery schedule, after-sales policy, and liability for breach of contract (e.g., a 1% deduction for each day of delayed delivery). Make the advance payment as agreed in the contract, and the supplier will commence production upon receipt of payment.

- Production tracking and on-site inspection: During the production process, you can visit the factory 1-2 times to check the production progress and quality control (such as cutting, sewing, and quality inspection). After production is completed, you can inspect the finished product on-site to check the quantity and quality. After confirming that everything is correct, you can pay the final payment and arrange logistics delivery.

Adaptive selection strategies for wholesale clothing suppliers of different categories

The production processes and quality requirements for different clothing categories (such as casual wear, business wear, and sportswear) vary greatly. When selecting suppliers, it is necessary to develop an adaptation strategy based on the characteristics of the category. This is also the focus of the "How to Identify and Select Clothing Wholesale Suppliers" section.

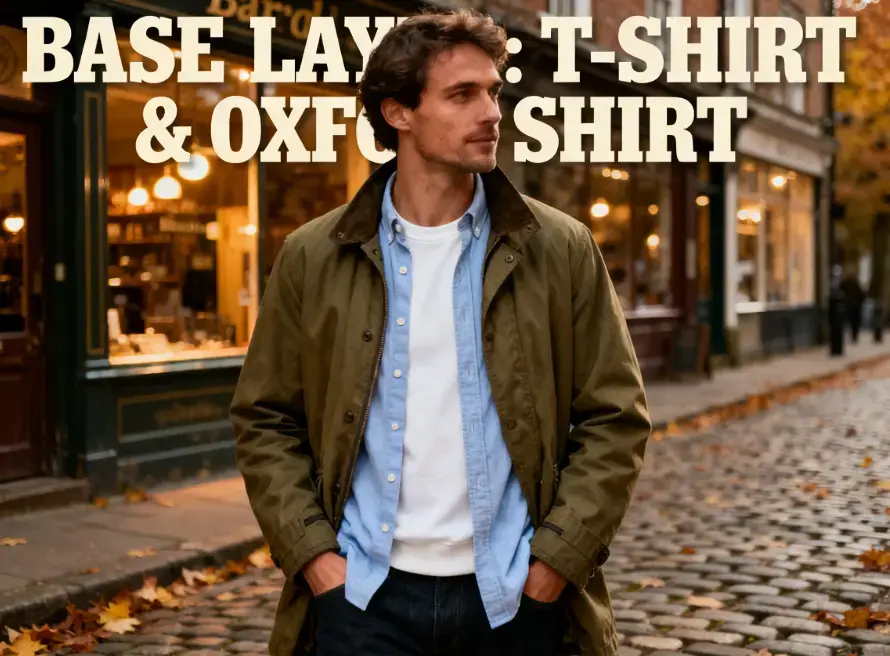

Casual wear wholesale supplier selection (e.g. T-shirts, hoodies, jeans)

- Core requirements: fast style updates, affordable prices, ample inventory, and durable and easy-care.

- Screening strategy:

a. Prioritize suppliers specializing in casual wear production, with at least three years of experience wholesale casual wear and familiarity with the aesthetics of young consumers (e.g., streetwear and minimalist styles);

b. Focus on fabric value. For example, choose 200-220g pure cotton terry for T-shirts (breathable and durable), and washed denim for jeans (fast-fading). Fabric costs must be kept within 40% of the wholesale price.

c. Confirm the speed of style updates: at least 20 new products per month, with a regular style inventory of 300 or more pieces, and support small trial orders (minimum 50 pieces) to meet merchants' needs for rapid product launches and trial sales.

Business attire wholesale supplier selection (such as shirts, suits, business suits)

- Core requirements: High-end quality, a well-fitted fit, crisp fabric, and exquisite details.

- Screening strategy:

a. Select suppliers with specialized business suit production capabilities, a professional pattern design team (e.g., offering three or more suit fits: slim, regular, and loose), and familiarity with business attire requirements (e.g., wrinkle-resistant, wrinkle-free);

b. Focus on fabric quality, such as combed cotton and polyester-cotton blends for shirts (crisp and wrinkle-resistant), and wool and polyester blends for suits (premium texture). Fabrics must meet international quality standards (e.g., ISO 9001 certification);

c. Verify craftsmanship details, such as a stitch density of ≥10 stitches per 3cm for shirts, double-stitch reinforcement for cuffs and collars for suits, and metal or natural materials (e.g., horn buttons) for buttons, avoiding cheap plastic buttons.

Select wholesale suppliers of sportswear (e.g. sports T-shirts, yoga pants, sports jackets)

- Core requirements: Fabric functionality (breathability, quick-drying, stretchability), comfortable fit, and wear- and wash-resistant.

- Screening strategy:

a. Prioritize suppliers with sportswear production qualifications, experience serving sports brands or gym clients, and familiarity with the functional requirements of sportswear (e.g., yoga pants must be highly stretchy, sports jackets must be waterproof);

b. Verify fabric functionality. For example, choose quick-drying fabrics (moisture wicking rate ≥ 5g/h) for sports T-shirts and stretch fabrics containing spandex (elastic recovery rate ≥ 90%) for yoga pants. Suppliers can be asked to provide fabric test reports.

c. Focus on fit. For example, sportswear should be loose and non-restrictive (bust circumference 10-15cm larger than a regular fit), with ribbing at the cuffs and hem (to fit snugly to prevent slipping during exercise) to ensure comfort.

Select wholesale suppliers of children's clothing (e.g. children's T-shirts, jackets, dresses)

- Core requirements: Fabric safety (formaldehyde-free, fluorescent agent-free), loose fit, safety details (no sharp accessories), durable and washable.

- Screening strategy:

a. Select suppliers specializing in children's clothing with children's clothing safety certifications (such as China Class A standards and EU CE certification). Fabrics must pass formaldehyde and pH tests (formaldehyde content ≤ 20ppm);

b. Examine design details, such as buttons and zippers, which must be secure (tension ≥ 70N to prevent accidental ingestion by children), no sharp edges (if any raw edges are cut, they must be hemmed), and printing must use environmentally friendly inks (odorless and non-fading).

c. Confirm size coverage, such as supporting children's sizes from 80-140cm, loose fit (allowing for growth), regular style inventory of ≥ 200 pieces, and support for small batch replenishment (minimum 30 pieces) to meet the demand for frequent new children's clothing releases.

Key points to avoid risks in cooperation with wholesale clothing suppliers

In the "How to Identify and Select Clothing Wholesale Suppliers" process, risk mitigation is key to ensuring long-term partnerships. Potential risks (such as quality issues, payment disputes, and contract pitfalls) must be identified in advance and targeted preventative measures must be developed.

Avoid the risk of "quality discrepancy"

- Risk manifestation: Significant quality discrepancies between the finished batch and the sample (e.g., fabric differences, poor workmanship, dimensional deviations), resulting in the product being unsalable.

- Preventative measures:

a. Sign a "Sample Confirmation Agreement" before cooperating. This agreement specifies the sample's fabric composition, workmanship details, and sizing chart, and explicitly states that "mass production must be consistent with the sample." Both parties must sign and seal the agreement.

b. Agree on quality acceptance standards in the contract (e.g., referencing the GB/T 29862 clothing standard) and specify a sampling inspection ratio (e.g., 10% of the order quantity). If the sampling fails, the supplier will be required to rework or redo the product.

c. When placing small trial orders, thoroughly test the finished product's quality (e.g., wash it five times for color fastness and test it for comfort). Only place a full order after the trial order passes, avoiding direct large-scale purchases.

Avoid the risk of "payment disputes"

- Risk manifestations: After payment, the supplier may not deliver, deliver less than the original shipment, or require additional "hidden fees" (such as expedited delivery or packaging fees), resulting in financial losses.

- Preventative measures:

a. Adopt a "staged payment" approach, such as a 30% down payment (payable upon order placement), a 30% progress payment (payable upon completion of production), and a 40% final payment (payable upon acceptance), to avoid a lump sum payment.

b. Pay through a public account and retain bank transfer receipts and invoices to avoid private transfers (which are difficult to trace).

c. Clearly include a "cost breakdown" in the contract, clearly indicating all costs (such as fabric, labor, and shipping), without ambiguous statements (such as "other costs will be charged separately"). Additional costs must be paid only after written confirmation by both parties.

Avoiding the risk of “contract traps”

- Risk manifestations: Ambiguous contract terms (e.g., delivery time stated as "approximately 7 days"), imbalanced rights and responsibilities (e.g., only binding on the merchant, not the supplier), and the supplier shirking responsibility when problems arise.

- Preventative measures:

a. The contract must clearly define key information, such as product specifications (category, quantity, size, material), price (unit price, total price, payment method), delivery time (accurate to the year, month, and day), delivery location (e.g., "delivery to XX warehouse"), and after-sales policy (defective product handling, replacement of unsold goods).

b. Clarify the liability of both parties for breach of contract. For example, the supplier will deduct 1% of the payment for each day of delayed delivery. If the delay exceeds 7 days, the merchant has the right to terminate the contract and request the return of the advance payment. The merchant will pay a penalty of 0.5% for each day of overdue payment. Rights and responsibilities must be balanced.

c. For complex contracts (e.g., with an annual purchase amount of ≥100,000 yuan), it is recommended to consult a legal professional to review the legality of the terms and avoid "unfair" clauses (e.g., "the supplier is not responsible for quality issues").

Avoid the risk of "long-term unstable cooperation"

- Risks: Initially, quality and delivery meet expectations, but later, problems such as declining quality, arbitrary price increases, and poor service attitudes may occur, impacting the merchant's business.

- Preventative Measures:

a. When signing a long-term cooperation agreement, include a "quality assurance clause," requiring that quality remain consistent with the initial order during the long-term cooperation period. If quality deteriorates, the merchant has the right to request a price reduction or terminate the cooperation.

b. Define a price adjustment mechanism. If fabric price increases lead to higher costs, the supplier must notify the merchant in writing 30 days in advance, and both parties must negotiate a new price to avoid unilateral and sudden price increases.

c. Establish a regular communication mechanism, such as monthly review meetings, to provide feedback on issues in the cooperation (such as quality and delivery), jointly develop improvement plans, and maintain a long-term, stable cooperative relationship.

Conclusion

Through the above content, I believe you have a comprehensive and clear understanding of "How to Identify and Select Clothing Wholesale Suppliers". From accurately identifying reliable suppliers, clarifying the core screening dimensions, to the online and offline docking process, different category adaptation strategies, and risk avoidance points, each step revolves around "matching needs, ensuring quality, and stable cooperation."

As a full-category clothing wholesale supplier, Dongguan Siyinghong Garment always takes the needs of merchants as the core. Whether it is casual wear, business wear or sportswear, it can provide high-quality, cost-effective products and complete after-sales support. At the same time, it supports small-batch trial orders and flexible replenishment to help merchants reduce procurement risks and improve market competitiveness. Choosing the right clothing wholesale supplier is a key step to the success of the clothing business. I hope this article can provide practical guidance for your screening work.

FAQ

FAQ 1:How can you quickly determine whether a wholesale clothing supplier is a "factory" or a "middleman"?

There are three ways to determine this: First, request a video of the factory or conduct a video inspection. Middlemen often cannot provide authentic factory footage. Second, ask for production details (such as fabric cutting methods and sewing equipment models). Factories can provide detailed answers, while middlemen are often vague. Third, check delivery times. Factory orders typically take 3-5 days, while middlemen, due to forwarding orders to the factory, often take more than 7 days.

FAQ 2:For the first cooperation, what is a reasonable quantity for a small trial order?

The recommended trial order quantity varies by product category: 50-100 pieces are recommended for casual wear (e.g., T-shirts and sweatshirts), 30-50 pieces are recommended for business wear (e.g., shirts and suits), and 30-50 pieces are recommended for children's wear. The trial order quantity should balance cost control and quality verification, testing the supplier's production capacity without causing the supplier to ignore the order due to a small order.

FAQ 3:Can the minimum order quantity for wholesale clothing be negotiated lower?

Most suppliers support negotiating minimum order quantities, especially for merchants with high potential for long-term cooperation. During the negotiation, you can explain your specific situation (e.g., a startup or trial sales need) and promise to expand the purchase scale if the trial order is successful. Some suppliers, to attract new customers, may reduce the minimum order quantity to 50% of the regular requirement (e.g., a regular minimum order of 100 pieces to a negotiated minimum of 50 pieces), but this may require a slight increase in the unit price (e.g., a 5%-10% increase per piece).

FAQ 4:What should I do if I find defective wholesale clothing after receiving it?

First, count the number of defective products and the types of problems (such as holes, missing stitches, and size deviations), and take clear photos as evidence; then, contact the supplier within the after-sales period (such as within 7 days of receipt) and apply for processing according to the contract (such as free reissue, deduction from the next payment); if the supplier shirks responsibility, you can protect your rights according to the after-sales terms in the contract, such as complaining to the platform (online cooperation) or resolving it through legal means (large orders).