Global T-Shirt Manufacturers Analysis and Production Process Guide

As the world’s most popular casual apparel item, T-shirts have become a core category in the fashion industry due to their versatility and customization potential. Driven by both fast fashion trends and sustainability imperatives, top T-shirt manufacturers must balance mass production (global annual capacity exceeds 10 billion units) with personalized customization. However, the primary challenge today lies in selecting partners from thousands of producers who excel in craftsmanship, environmental responsibility, and service flexibility. This guide provides a systematic solution through end-to-end production analysis and supplier evaluation frameworks.

Full-Lifecycle Production Process Breakdown

2.1 Creative Design Engineering

Modern design processes follow a three-dimensional system of "inspiration capture - digital modeling - market validation":

- Concept Visualization: 2D sketches are created using professional software like Adobe Illustrator, followed by 3D virtual sampling with CLO 3D.

- Data-Driven R&D: Intelligent design systems integrate ergonomic databases (covering body shape data from different regions).

- Trend Forecasting: Prospective design modules (e.g., 2024’s deconstructivist cuts) are developed in collaboration with platforms like WGSN.

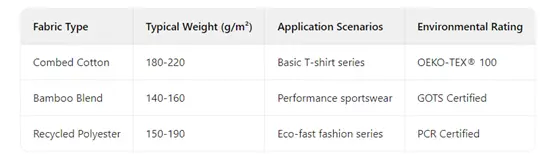

2.2 Fabric Science and Selection

Fabric engineering serves as the foundation of quality control, requiring a three-dimensional evaluation model of "functionality - cost - sustainability":

2.3 Industrialized Pattern Making

Smart pattern-making systems are revolutionizing traditional craftsmanship:

- Laser Cutting: 500W CO₂ laser equipment achieves 0.1mm precision cutting.

- Digital Printing: Mimaki TX800 series supports 600dpi high-precision printing, with colorfastness meeting ISO 105-B02 Grade 4 standards.

- Intelligent Stitching: Yamato automatic linking machines with vision inspection systems enable standardized production at 30 units per minute.

2.4 Quality Control System

A three-tier quality inspection system compliant with ISO 9001:2015 is implemented:

- Raw Material Inspection: ASTM D3776 fabric weight testing and EN 29073-2 colorfastness tests are conducted.

- In-Process Inspection: 1 out of every 50 finished products is sampled for full-dimension measurement (tolerance control ±1.5mm).

- Final Inspection: Durability is verified through light aging tests (QUV equipment simulating 500 hours of sunlight exposure).

3. Sustainable Manufacturing Transformation

The industry is undergoing a "green revolution," with leading practices including:

- Material Innovation: Patagonia uses 100% organic cotton and plant-based dyes, reducing water consumption by 71%.

- Energy Upgrades: Adidas’ Southeast Asian factories employ solar power systems, cutting carbon footprints by 45%.

- Circular Economy: H&M’s "T-Shirt Recycling and Reconstruction" program achieves an 85% recycling rate for old garments.

4. Supplier Evaluation Matrix

When selecting partners, the RATER model is recommended for comprehensive assessment:

- Reliability: Review ISO 14644-1 cleanroom certifications and three-year on-time delivery rate data.

- Assurance: Request AQL 2.5 sampling inspection reports and CE certification documents.

- Responsiveness: Test sample delivery cycles (premium Manufacturers typically require ≤7 working days).

- Empathy: Evaluate low-volume customization capabilities (e.g., flexible production systems with MOQs ≤500 units).

- Tangibility: Conduct on-site audits of smart factories (focus on MES system coverage and automation equipment ratio).

5. Mainstream Category Innovation Trends

5.1 Functional Products

- Outdoor Series: Integrated with UPF 50+ sun protection and Polygiene® anti-mosquito antibacterial technology.

- Smart Wearables: Interactive T-shirts with embedded NFC chips enable real-time brand information retrieval.

5.2 Sustainable Categories

- Mycelium Biomaterials: Bolt Threads’ Mycelium™ fabric achieves 100% biodegradability.

- Ocean Plastic Recycling: The OceanCycle™ series uses polyester fibers derived from coastal fishing net waste.

5.3 Cultural IP Collaborations

- Museum Licensing Series: The Louvre × UNIQLO Mona Lisa print T-shirt sold out within the first week of launch.

- Esports Co-Branded Models: The Riot Games × Nike League of Legends limited-edition T-shirt carried a 300% premium.

6. Digital Procurement Strategies

A "three-pronged" supplier development system is recommended:

- B2B Platforms: Use vertical platforms like Maker's Row and Thomasnet to build initial shortlists.

- Social Media: Track designer brand collaborators on Pinterest and source supply chain executives via LinkedIn.

- Industry Exhibitions: Prioritize participation in CENTRESTAGE (Hong Kong) and ISPO (Germany).

Conclusion

Over the next five years, the T-shirt manufacturing industry will focus on three trends: technological intelligence, localized production, and green value creation. Enterprises must adopt next-generation manufacturing systems integrating flexible supply chains, digital twin factories, and carbon footprint management, while leveraging blockchain technologies (e.g., IBM Food Trust™) for end-to-end traceability from cotton fields to wardrobes. It is recommended that buyers implement dynamic supplier scoring systems, updating key indicators such as technological innovation and social responsibility performance on a quarterly basis to adapt to rapidly evolving market demands.

Translation Notes:

1.Professional Tone: Maintained industry-specific terminology (e.g., ISO standards, technical processes) while ensuring readability for international audiences.

2.Data Emphasis: Retained quantitative metrics (e.g., 71% water reduction) to reinforce credibility.

3.Logical Flow: Followed a problem-solution-trend structure typical of Western business reports.

4.Brand Examples: Kept globally recognized brand cases (Patagonia, Adidas) to enhance relatability.

5.Format Consistency: Preserved table structures and model frameworks for analytical clarity.