From Idea to Reality Custom Clothes Handbook

Whether you're a fashion entrepreneur building a brand, customizing employee uniforms for a company, or designing personalized apparel for yourself, the "From Idea to Reality Custom Clothes Handbook" is a crucial guide for navigating the critical path from idea to finished product. Many people harbor unique custom ideas, but lack a clear understanding of requirements analysis, partner selection, or process control, leading to significant deviations from expectations and even abandonment of the project midway. With 12 years of experience in custom clothing services, Dongguan Siyinghong Garment has helped over 300 clients transform their "abstract ideas" into "real garments," covering a wide range of categories, including casual wear, business wear, sportswear, and workwear. This article, focusing on practicality, systematically explains the "From Idea to Reality Custom Clothes Handbook" from perspectives such as requirements conversion, partner selection, process breakdown, quality control, and problem solving, ensuring your custom clothing ideas can be efficiently and smoothly realized.

How to transform custom clothing ideas into clear demand plans?

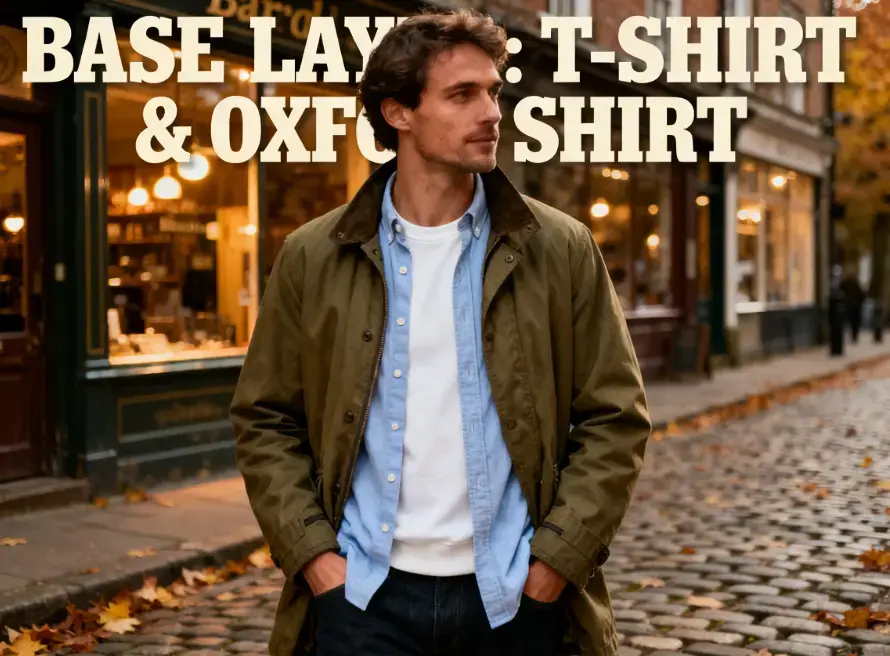

"Converting vague ideas into actionable requirements" is the first step in the "From Idea to Reality Custom Clothes Handbook" and is fundamental to the success of custom clothing. Many clients initially describe only "I want a nice Custom jacket," but lack crucial details, leading to back-and-forth in subsequent communication.

Dongguan Siyinghong Garment recommends using a "five-dimensional needs analysis method" to transform abstract ideas into clear solutions:

1. Clarify customization goals and scenarios: First, determine the core purpose of the custom clothing—whether it's a brand launch (must meet the target customer's aesthetic), corporate workwear (must reflect the brand image and be practical), event-specific clothing (must highlight the theme and be easily recognizable), or personal everyday wear (must meet comfort and personal needs). Also, clearly define the usage scenario (e.g., outdoor in the summer, indoor in the winter, formal occasions). This directly influences the selection of fabric, pattern, and craftsmanship (e.g., waterproof fabric for outdoor clothing, hardwear for workwear).

2. Identify core design elements: Identify the key design points in your idea, breaking it down into four dimensions: style (minimalist, retro, streetwear), primary color (Pantone color code or reference color chart required), pattern (logo, illustration, text, with specific size and placement), and special details (such as custom buttons, contrasting stitching, and detachable accessories). If you lack design inspiration, provide references (such as similar styles from a certain brand or outfits worn by fashion bloggers). The factory design team can assist with optimization.

3. Determine the clothing category and fit parameters: Identify the specific category of custom clothing (such as dresses, sweatshirts, shirts, and jackets) and provide fit requirements—whether it's a loose fit (suitable for casual occasions), a slim fit (suitable for business occasions), or an oversized fit (in line with trendy trends). Also provide key measurement references (such as length, chest circumference, and shoulder width). Provide measurements of similarly fitteD Clothing or specify the target size range, such as S-XL for women and M-XXL for men).

4. Fabric and trim selection: Based on the scenario and objectives, choose the appropriate fabric type—cotton (breathable and comfortable, suitable for everyday wear), polyester (wear-resistant and wrinkle-resistant, suitable for workwear), wool (warm and high-end, suitable for winter outerwear), or stretch fabric (suitable for sportswear). Also, determine trim requirements (such as zipper brand, button material, and whether the printing ink is environmentally friendly; for children's clothing, choose trims without fluorescent agents).

5. Clarify order size and delivery time: Determine the custom quantity (e.g., 50 pieces for a trial run, 500 pieces for a batch order). This will affect the factory's minimum order quantity policy and quote. Also, clarify the delivery timeline (e.g., requiring delivery 10 days before the event). The factory can work backwards from this timeline to avoid delays in production planning.

Through these five steps, you can transform vague ideas into actionable and unambiguous requirements, laying the foundation for future collaboration.

Screening criteria and evaluation methods for custom clothing partners

Choosing the right partner is crucial for realizing your custom clothing ideas and is a core component of the "From Idea to Reality Custom Clothes Handbook." Choosing the wrong partner can lead to issues like design fidelity, substandard quality, and delayed delivery, resulting in wasted time and money.

Dongguan Siyinghong Garment has summarized four core screening criteria to help you accurately identify the right custom partner:

1. Customization Capabilities and Category Experience: Prioritize partners who specialize in custom services and have experience in the corresponding category. For example, for custom workwear, look for a factory with a track record of providing corporate workwear services, while for customizing high-end formal wear, look for a team with advanced sewing techniques. You can request to review past custom case studies (e.g., the degree of design fidelity and finished product details for the same category) and inquire about whether a small trial run (e.g., 20-50 pieces) is available to avoid deviations in the final product due to a partner's lack of experience.

2. Design and R&D Support Capabilities: Evaluate whether the partner provides full-process support from idea to design. If you only have a preliminary idea, confirm whether they have a professional design team (who can provide design sketches and 3D renderings). If you already have a design draft, inquire whether they can conduct a feasibility assessment (e.g., whether complex patterns can be achieved through printing, whether special patterns are suitable for production), and provide optimization suggestions (e.g., adjusting fabric selection to reduce costs).

3. Production Capabilities and Delivery Guarantees: Examine the partner's production hardware and capacity. Whether they have independent custom production lines (to avoid mixed production with mass-produced garments and resulting quality instability) and whether they are equipped with specialized custom processing equipment (e.g., digital printers, laser cutters). Also confirm their delivery capabilities. Based on your order volume and turnaround time requirements, inquire about standard customization lead times (e.g., 15-20 days for small orders, 30-45 days for large orders) and emergency order processing options (e.g., whether expedited delivery times of 7-10 days are possible).

4. Service Details and After-Sales Policies: Pay attention to the partner's service process and after-sales guarantee - whether free sample making is provided (most high-quality customization parties will provide 1-3 samples), whether there is a dedicated contact person (responsible for demand communication and progress feedback), and how after-sales quality issues are handled (such as the return and exchange time limit for defective products and the pattern adjustment plan). For example, after the sample is confirmed, a professional partner will sign a detailed contract to clarify the design requirements, quality standards, delivery time and breach of contract liability to protect the rights and interests of both parties.

Practical Tips for Partner Assessment

• On-site or video factory inspection: For large orders (e.g., over 100 pieces), you may request an on-site visit to the partner's factory to inspect the production environment, equipment, and quality inspection procedures. If an on-site visit is not possible, you can request a video conference to gain a firsthand understanding of the production capabilities.

• Sample testing and verification: Upon receipt of samples, we conduct multi-dimensional testing—including fabric testing (for pilling and color fading after washing), workmanship testing (for print durability and seam breakage), and pattern testing (for comfort and fit)—to ensure that the samples meet expectations before proceeding to mass production.

• Customer reputation research: Through industry platforms, social media, or the customer contact information provided by the partner, we can understand past customer experiences (such as design fidelity, delivery timeliness, and after-sales response speed) to avoid choosing partners with poor reputations.

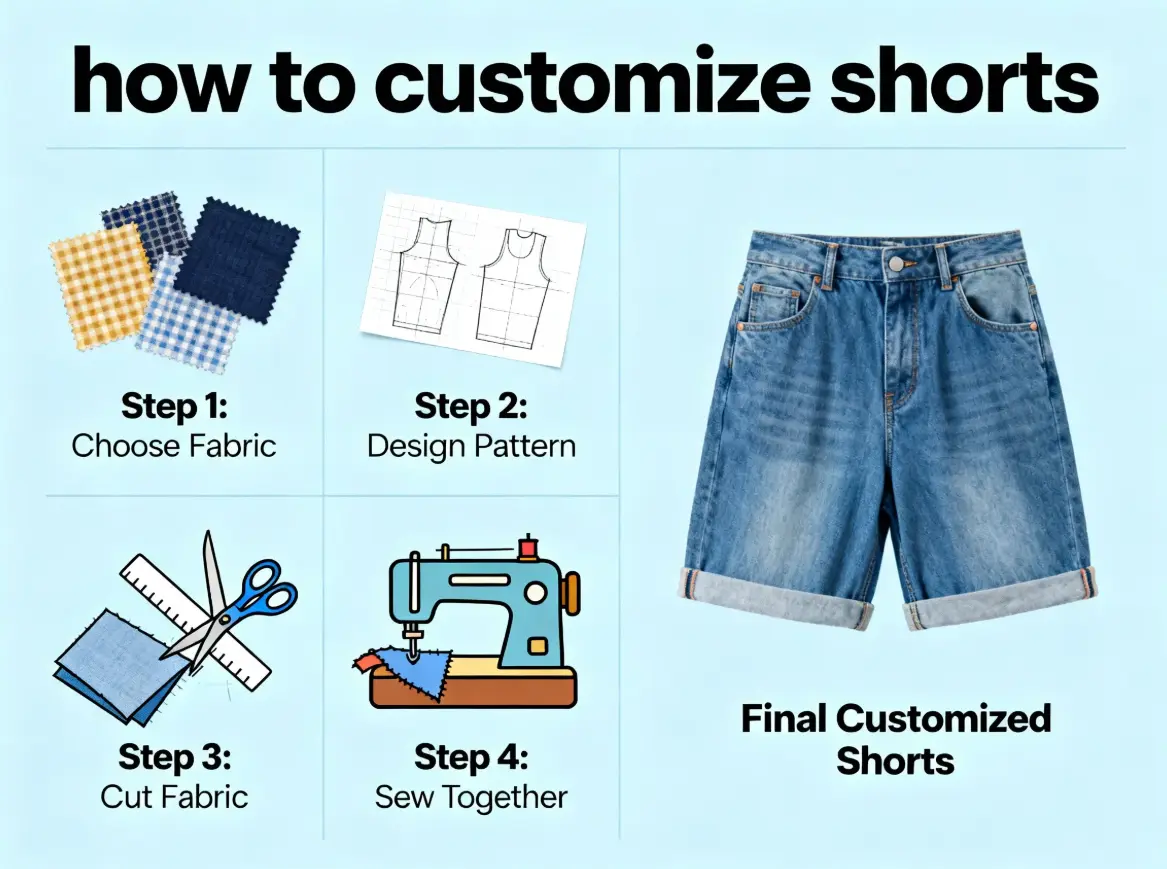

From design to delivery: a breakdown of the entire custom clothing process

A clear customization process makes the implementation of ideas more controllable and efficient, and is the core content of the "From Idea to Reality Custom Clothes Handbook." Many clients, lacking understanding of the process, frequently experience anxiety during the production process, and even experience problems due to communication breakdowns.

Dongguan Siyinghong Garment has developed a "7-step standardized implementation process" for custom clothing, covering the entire process from design to delivery:

1. Requirements Communication and Design Confirmation: You provide a streamlined design proposal (including design ideas, fabric selection, and size requirements). The partner's design team will draw design sketches or 3D renderings based on these requirements. Both parties will communicate and make adjustments (such as modifying pattern placement or optimizing color matching) until the design is confirmed.

2. Process Feasibility Analysis and Quotation: Based on the design proposal, the partner will assess the process feasibility (e.g., whether complex embroidery can be implemented, whether there are sourcing channels for special fabrics), provide a detailed quotation (including fabric fees, design fees, processing fees, labor costs, and shipping costs), and specify payment methods (e.g., 30% down payment, 70% final payment).

3. Sample Production and Confirmation: Our partners will produce samples based on the confirmed design, annotating the fabric composition, process details, and dimensional parameters. Upon receipt of the samples, you will try them on, test them, and inspect them in detail. If you suggest any modifications (e.g., adjusting shoulder width or changing fabric color), our partners will make modifications free of charge until the samples meet your standards.

4. Pre-production Preparation and Material Procurement: After sample confirmation, our partners will purchase raw materials (e.g., custom fabrics, accessories, and printing inks) based on the order volume and conduct pre-production adjustments (e.g., adjusting printing equipment parameters and confirming sewing process standards) to ensure that production conditions meet your custom requirements.

5. Mass Production and Progress Tracking: After mass production begins, our partners will synchronize progress (e.g., fabric cutting completed, printing midway through, sewing completed) in real time through a dedicated chat group. They will also provide photo or video feedback at key milestones (e.g., 20%, 50%, and 80% of production), allowing you to stay informed of production progress.

6. Finished Product Inspection and Quality Control: After production is complete, our partners conduct a full inspection of each piece, checking for design fidelity (whether pattern placement and color match the sample), workmanship (whether seams are secure and prints have not fallen off), sizing (whether length and bust variations are within acceptable limits), and appearance (for stains and loose threads). Defective products will be individually marked and reworked.

7. Packaging and Delivery: Qualified finished products will be packaged according to your specifications (e.g., customized brand packaging, individual dust bags), and appropriate logistics methods will be selected (e.g., domestic express, international sea/air freight), with a tracking number provided. Upon delivery, our partners will assist in confirming receipt and answer any questions regarding subsequent wear and care.

Key communication points in the process

- • When confirming the design plan: Be sure to confirm the design details in writing (e.g., email, contract attachment), including renderings, size charts, and fabric specifications, to avoid subsequent disputes due to "verbal agreements."

- • When modifying samples: Each time you propose a modification, be sure to clearly specify the adjustment point (e.g., "Shorten the cuff length by 2cm," "Change the chest logo color from red to dark red (Pantone color 186C)") to avoid vague statements that may lead to incomplete modifications.

- • When the production schedule is abnormal: If your partner reports a delay, promptly communicate the cause and solution (e.g., whether delivery needs to be split up, and whether there are any compensation measures) to ensure that your usage plans are not affected.

The importance of small batch trial production

If you are customizing for the first time (such as a brand's first product), it is recommended to conduct a small-scale trial production (such as 30-50 pieces) first. Through the trial production, you can verify the market acceptance of the design (such as the target customer group's evaluation of the style and fabric), the production capacity and quality stability of the partner, and then optimize the plan based on the trial production results to promote large-scale customization and reduce investment risks.

Key links in quality control in custom clothing production

Quality is the core value of custom clothing and a key focus in the "From Idea to Reality Custom Clothes Handbook." Failure to ensure quality control can render the finished product uncompetitive, even the most exceptionally well-designed, and even damage brand reputation.

Dongguan Siyinghong Garment has established a three-stage quality control system to ensure the quality of custom clothing from source to finished product:

1. Raw material quality control (pre-production stage)

◦ Fabric testing: Purchased fabrics must pass composition testing (e.g., if labeled as 100% cotton, the actual composition error must not exceed 5%), color fastness testing (washing and rubbing color fastness must reach level 4 or higher to prevent fading), and physical property testing (e.g., tensile strength and abrasion resistance; workwear fabrics must withstand at least 500 abrasions). Unqualified fabrics will be returned directly to the supplier. ◦ Accessory screening: Accessory materials (such as zippers, buttons, and printing inks) must meet safety standards (e.g., children's clothing accessories must have no sharp edges, and environmentally friendly inks must contain ≤20ppm formaldehyde). Sample testing is also required (e.g., zippers must be able to pull 100 times without sticking, and buttons must withstand a pulling force of ≥70N to prevent detachment).

2. Quality Control During the Production Process (Mid-Production Stage)

◦ Cutting: Automated cutting equipment is used to ensure that the size deviation of the cut pieces is ≤1cm. Each piece is labeled with the corresponding size and part (e.g., "Left Front - Size S") to prevent mixed stocking and pattern errors. Pieces are also inspected for defects (e.g., holes in the fabric, uneven yarns), and any defective pieces are replaced promptly. ◦ Processing: Different processes have their own quality inspection standards. For printing, the clarity of the pattern (no blurring or missing prints) and position deviation (≤0.5cm) must be checked. For embroidery, the stitch density (no missed stitches or hooked threads) and seam smoothness must be checked. For sewing, the thread density (≥8 stitches per 3cm) and the presence of skipped stitches and broken threads must be checked. Key areas (such as cuffs and necklines) must be double-sewn for reinforcement.

◦ Semi-finished product inspection: During the production process, quality inspectors must sample ≥10% of semi-finished products after each step (such as cutting, printing, and sewing). Any problems found will be immediately stopped and corrected to prevent them from being passed on to the next stage.

3. Finished Product Quality Control (Post-Production Stage)

◦ Full Inspection Process: After the finished product is completed, it undergoes a piece-by-piece inspection to verify design fidelity (comparing the pattern, color, and size with the sample), workmanship integrity (e.g., print integrity, embroidery integrity), and appearance neatness (no stains, thread ends, or holes). A fitting test is also conducted (a random sample of finished products in different sizes is tested for fit and comfort).

◦ Sampling Testing: 5% of the finished product is randomly sampled for specialized testing, including a wash test (simulating daily washing five times to check for pilling, discoloration, and deformation), a friction test (checking for wear resistance of the print/embroidery), and a dimensional stability test (size deviation ≤3% after washing). Only qualified garments can be shipped.

◦ Pre-packaging Re-inspection: Before shipment, the finished product packaging is re-inspected to ensure compliance with requirements (e.g., for damage or incorrect labeling), ensuring that every custom garment delivered to you meets quality standards.

Clear agreement on quality standards

Before cooperating, it is necessary to clarify the quality standards with the partner (such as referring to the GB/T 29862 clothing standard and the AATCC textile testing standard), and specify the specific requirements in the contract (such as "the color fastness of the fabric must reach level 4 or above" and "the seams must not be skipped or broken") to avoid disputes over quality certification later.

Practical strategies to solve common problems in custom clothing landing

While implementing the "From Idea to Reality Custom Clothes Handbook," you'll inevitably encounter various problems. Knowing the solutions ahead of time can reduce communication costs and ensure a smooth customization process. Dongguan Siyinghong Garment has compiled five common problems and their corresponding solutions:

What should I do if the design plan cannot be implemented?

If a partner reports that a design proposal presents technical difficulties (e.g., a complex pattern that cannot be printed, or a special pattern that is difficult to sew), a "three-step optimization approach" can be implemented:

1. Ask the partner to provide a specific explanation of the problem (e.g., "The pattern details are too fine, and digital direct printing cannot reproduce them; we recommend simplifying the lines");

2. Adjust the design proposal based on technical feasibility (e.g., simplifying pattern details, changing the appropriate process, or adjusting the pattern structure);

3. Request the partner to produce a "process test sample" (testing only the adjusted key process) and confirm feasibility before moving forward with the overall design.

What to do if the sample is qualified but there are deviations in the batch of finished products?

If there are discrepancies between the finished batch and the qualified sample (e.g., color inconsistency, significant dimensional deviation), we must communicate with our partners immediately:

1. Provide comparison photos of the discrepancies (marking the specific differences, e.g., "Sample color is Pantone 186C, finished batch is Pantone 199C");

2. Request the partners to investigate the cause (e.g., fabric batch differences, production process parameter adjustments);

3. Negotiate a solution: Minor discrepancies (within an acceptable range) may result in a discount; major discrepancies (impairing usability) may result in rework (costs borne by the partners) or a return and refund.

How to deal with the impact of customization cycle delay on usage plan?

If a partner experiences a delay due to raw material shortages, equipment failure, or other reasons, the following measures can be implemented:

1. Require the partner to provide detailed reasons for the delay and a new delivery timeline;

2. If the product is urgently needed, negotiate for partial delivery (prioritizing delivery of some finished products as an emergency measure);

3. Define a compensation plan for the delay (e.g., a 1% discount on the order value for each day of delay, or a free process upgrade for the next custom order) and include this provision in the contract.

How to adjust if the customization cost exceeds the budget?

If the initial quote exceeds your budget, you can optimize costs along four dimensions:

1. Fabric Adjustment: Choose a more cost-effective alternative fabric (e.g., using a pure cotton blend instead of 100% cotton can reduce costs by 15%-20%).

2. Process Simplification: Reduce complex processes (e.g., using screen printing instead of digital direct printing can reduce costs for mass customization by over 25%).

3. Order Quantity Adjustment: If your partner supports a small-batch trial run, you can reduce the order quantity to minimize initial investment.

4. Delivery Cycle Adjustment: Choose a non-urgent production cycle (e.g., avoiding peak season). Some partners may offer price discounts.

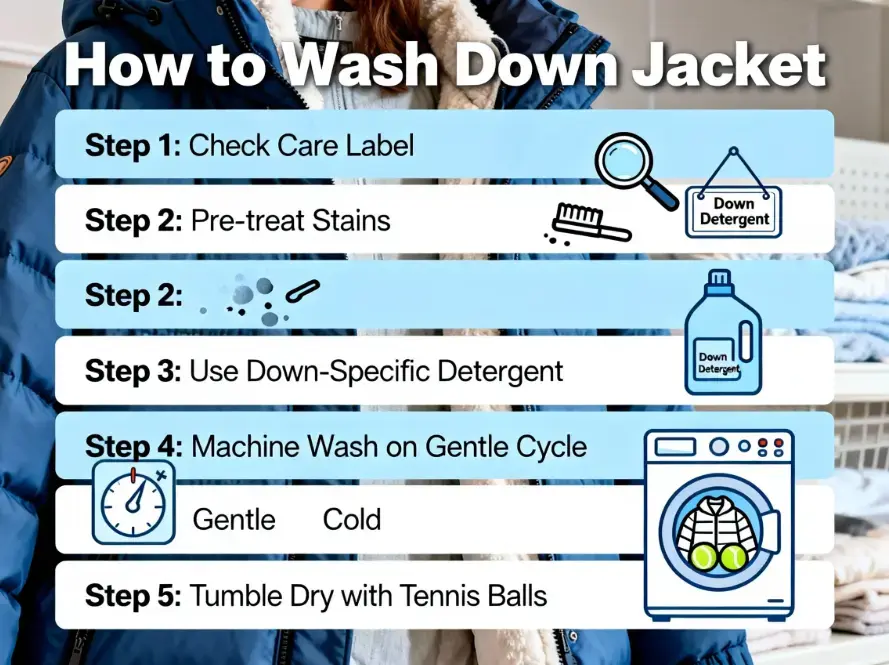

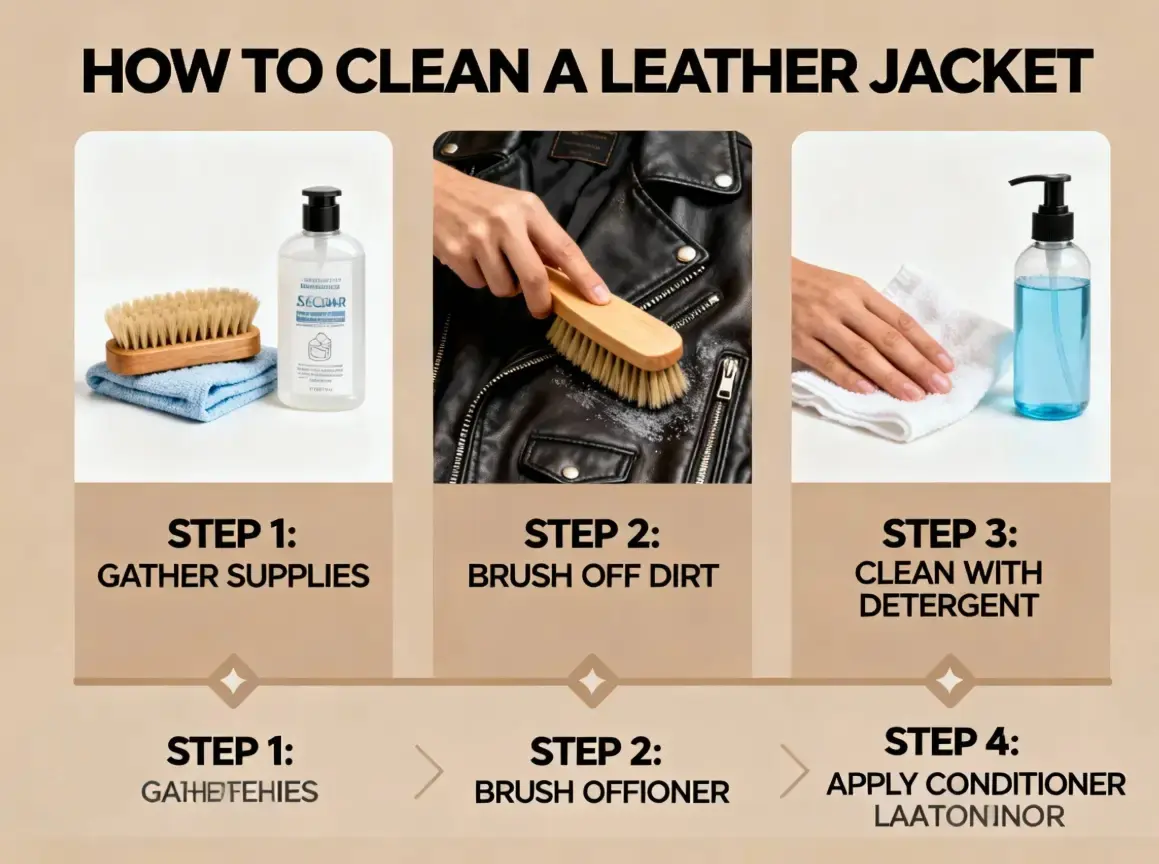

How to solve the follow-up care and after-sales problems of customized clothing?

After receiving your custom garment, if you have any care questions (e.g., machine washability, low-temperature ironing required) or after-sales issues (e.g., seams detaching after several wears):

1. Care questions: Contact the partner to obtain a "dedicated care guide" (which provides specific recommendations based on the fabric and craftsmanship);

2. After-sales issues: Within the after-sales guarantee period (most partners offer 30-90 days), provide photos of the problem and proof of purchase. The partner may provide free repairs, replacement parts, or appropriate compensation.

Conclusion

Through this systematic interpretation of the "From Idea to Reality Custom Clothes Handbook", I believe you have mastered the core methods of implementing custom clothing ideas - from the "5-dimensional demand analysis method" to transform vague ideas, to the "4 major screening criteria" to select reliable partners, to the "7-step standardized process" to promote production, and the "3-stage control system" to ensure quality, as well as practical strategies for dealing with common problems. Dongguan Siyinghong Garment has always been.