From fabric to version: reveal the five core processes of high-end men's wear customization

—— SiYinghong men's wear industry and trade, with ingenuity cast quality benchmark

In the field of high-end men's clothing customization , the degree of exquisite craftsmanship directly determines the texture and value of clothing. As an industry and trade enterprise that has been deeply engaged in men's wear industry for 16 years, we always believe that " the soul of customization lies in details, and the perfection of details comes from the ultimate pursuit of technology."This article will take you to in-depth understanding of high-end men's wear customization 5 core technology, reveal the whole process from fabric selection to the shape of the craftsmanship.

1. Fabric screening: one in a million-one quality starting point

Fabric is the "skin" of clothing, which directly affects the wearing experience and visual effect. Our process starts with the fabric screening:

- Global source: cooperate with Italy, Japan and other top fabric suppliers, select rare materials such as Merino wool, island cotton and silk blend.

- Physical testing: through 12 indicators, such as gram stress test, color fastness test, and wrinkle resistance analysis, to ensure that the fabric meets the high-end customized standards.

- Scene adaptation: Match fabric characteristics according to customer needs, such as recommending high-supported worsted wool (anti-wrinkle and easy to manage) in business scenes, and choosing linen blend (breathable and skin-friendly) in casual scenes.

Enterprise advantages: We build our own fabric laboratory to support small batch customized development, such as 2025, launched "intelligent temperature controlled wool", can adjust the air permeability according to the ambient temperature.

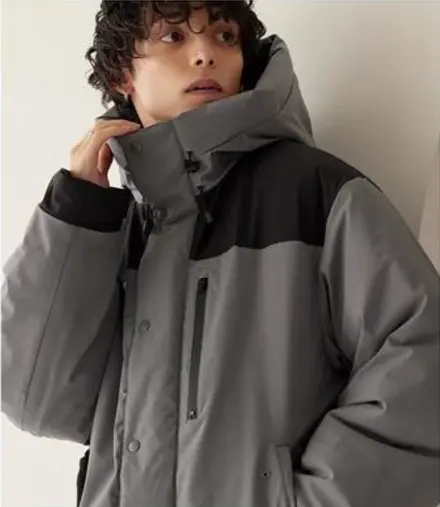

2. Body cutting: millimeter-level precision art

Volume is the core link of customization . We adopt the "three-dimensional volume + dynamic correction" dual-track system:

- 168 data collection: key data such as shoulder width, back length, chest and waist difference were manually measured by professional body markers, and captured body shape curve combined with 3D scanning technology.

- Dynamic fitting and correction: customers wear semi-finished products for walking, hand lifting and other actions, and adjust the cutting of frictional parts such as shoulder line and cuff hole in real time.

- Version database: based on the size data of millions, the Asian male exclusive version model is established to ensure that the fit degree of custom clothing reaches more than 98%.

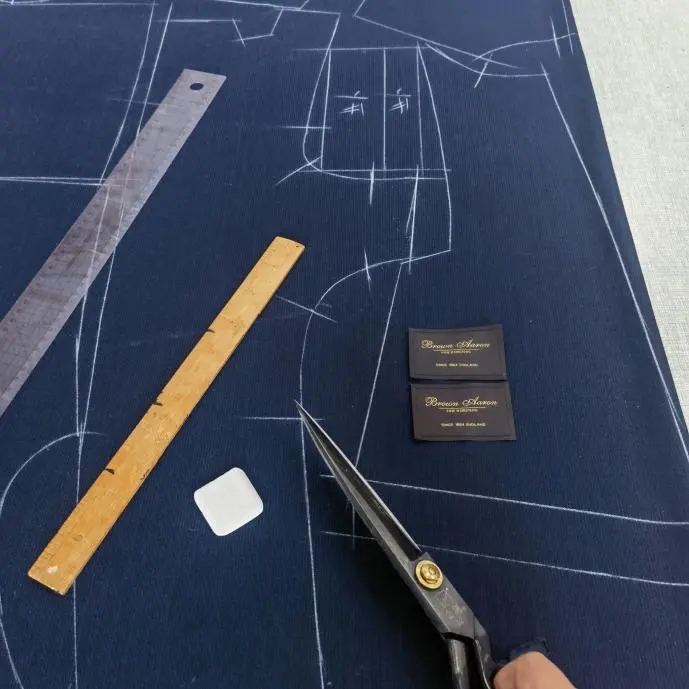

3. Sewing process: 0.1mm extreme control

Sewing is a key step in transforming fabrics into works of art. We use "segmented fine sewing":

- Component pretreatment: collar, cuff and other deformable parts are reinforced with inlet adhesive lining to ensure braces.

- Handmade dark seam: the use of "Milan eye" manual lock button hole, "half hemp lining" manual extraction technology, enhance the three-dimensional sense of clothing.

- 3D tailoring: Through multi-chip splicing technology, the smooth balance of the back and the natural arc of the abdomen.

Highlights of the enterprise: Each production line is equipped with an independent quality inspection station, and the triple inspection system of "first piece full inspection + process sampling inspection + reinspection of finished products" is adopted, and the rate of defective products is less than 0.03%.

4. Casting and setting: accurate control of temperature and humidity

Hot ironing is the "last shaping" of clothing, we use Italy imported automatic ironing equipment:

- Steam penetration: through high pressure steam softening fiber, combined with ergonomic mold, reshape the clothing profile.

- Humidity control: accurately adjust the humidity to 65% to avoid excessive high temperature damage to the fabric.

- Natural cooling: after pressing the static stand for 24 hours, so that the fiber naturally bounce back, to ensure the lasting stability of the version.

5. Details: a custom symbol with the finishing point

- Personalized logo: provide exclusive services such as cufflinks and interior embroidery, such as customer name abbreviations, family badges, etc.

- Functional design: hidden mobile phone bag, removable collar support and other practical details to improve the scene adaptation of clothing.

High-end men's wear customization is not only the combination of fabric and version, but also the dialogue between craftsmanship and ingenuity. Si Yinghong Clothing Co., Ltd., through five core processes, controls the quality from the source, enables the traditional tailoring skills with industry 4.0 intelligent manufacturing, and creates an exclusive experience of "one thing, one world" for global customers.

Start your custom tour immediately , leave your email phone message, book a professional designer, and let us sew you a "breathing second skin layer."