A Panoramic Guide to Screening and Collaborating with Chinese Hoodie Suppliers

For apparel brands, securing reliable, high-quality Chinese hoodie suppliers in a complex market presents a significant challenge. However, collaborating with Chinese suppliers offers significant advantages—effectively reducing costs, expanding production scale, and unlocking greater customization possibilities. This article provides a comprehensive and practical guide, from supplier discovery to final delivery, to help brands avoid partnership pitfalls and make informed business decisions.

1. Weighing the pros and cons of sourcing hoodies from China

As a global Clothing Manufacturing giant and the largest textile exporter, China possesses immense production capabilities and can transform nearly any brand's design concept into a physical product. However, before deciding to collaborate, it's important to objectively weigh the pros and cons:

| Advantages | Disadvantages |

| High cost performance | There is a language communication barrier |

| Advanced production technology and equipment | Some suppliers' quality control is not in place |

| Rich and diverse customized solutions | International logistics and tax processes are complex |

| The supply chain system is mature and stable | There is generally a minimum order quantity (MOQ) threshold |

2. Core Screening List for Chinese Hoodie Suppliers

Finding high-quality suppliers is not a simple search; it requires a multi-dimensional assessment and screening process. This can be divided into three key stages:

(1) Preliminary screening and background verification

The goal of this stage is to quickly eliminate unqualified suppliers, focusing on three dimensions:

1.Verify qualifications and certifications : Request a copy of the supplier's business license and confirm whether they have quality certifications such as ISO 9001. These documents are key to verifying the supplier's legitimacy and ensuring they adhere to industry quality standards.

2.Research online reputation and image : Browse the supplier's official website and its storefronts on B2B platforms like Alibaba and Global Sources. Delve into customer feedback in comment sections and industry forums to understand the supplier's true reputation.

3.Judging the professionalism of communication : Observe the supplier's response to your initial inquiry email. A reliable supplier will address your questions comprehensively and accurately. Be wary of a supplier that only responds with brief, perfunctory responses and fails to address key questions.

(2) Production capacity assessment

After the initial screening, it is necessary to further confirm whether the supplier can meet the brand's specific production needs:

1.Check past cases and portfolios : Ask suppliers to provide samples or case materials of hoodies they have produced in the past to visually judge their product craftsmanship and quality level.

2.Confirm the matching degree of professional fields : Understand whether the supplier specializes in a specific field, such as whether it excels in the production of heavy fleece fabrics, and whether it can provide special processes such as three-dimensional printing (puff print), so as to choose a partner that matches your own product positioning.

3.Clarify minimum order quantity requirements : Ask suppliers about their minimum order quantity to ensure it falls within your brand's purchasing budget and inventory planning. While recommended lists of hoodie Manufacturers within the industry can be used as a reference, brands should still independently review each one to avoid blindly partnering.

(3) Key links in sample evaluation

Sample testing is the "safety valve" before placing a batch order and must not be omitted:

1.Adhere to the principle of sample first : Regardless of the supplier's promise, you must order samples first. Only by touching and inspecting the samples yourself can you truly understand the product quality and avoid problems with subsequent batch orders.

2.Provide a detailed technical file (Tech Pack) : The technical file should include all details such as the hoodie's size parameters, fabric specifications, color standards, etc. Clear technical requirements can help suppliers accurately produce samples and reduce deviations.

3.Inspect samples according to the standard checklist : After receiving the samples, we conduct a comprehensive inspection from the feel and weight of the fabric, to the sewing neatness, color reproduction, and pattern adaptability to ensure that the samples meet expectations.

3. 5-step process for working with Chinese hoodie suppliers

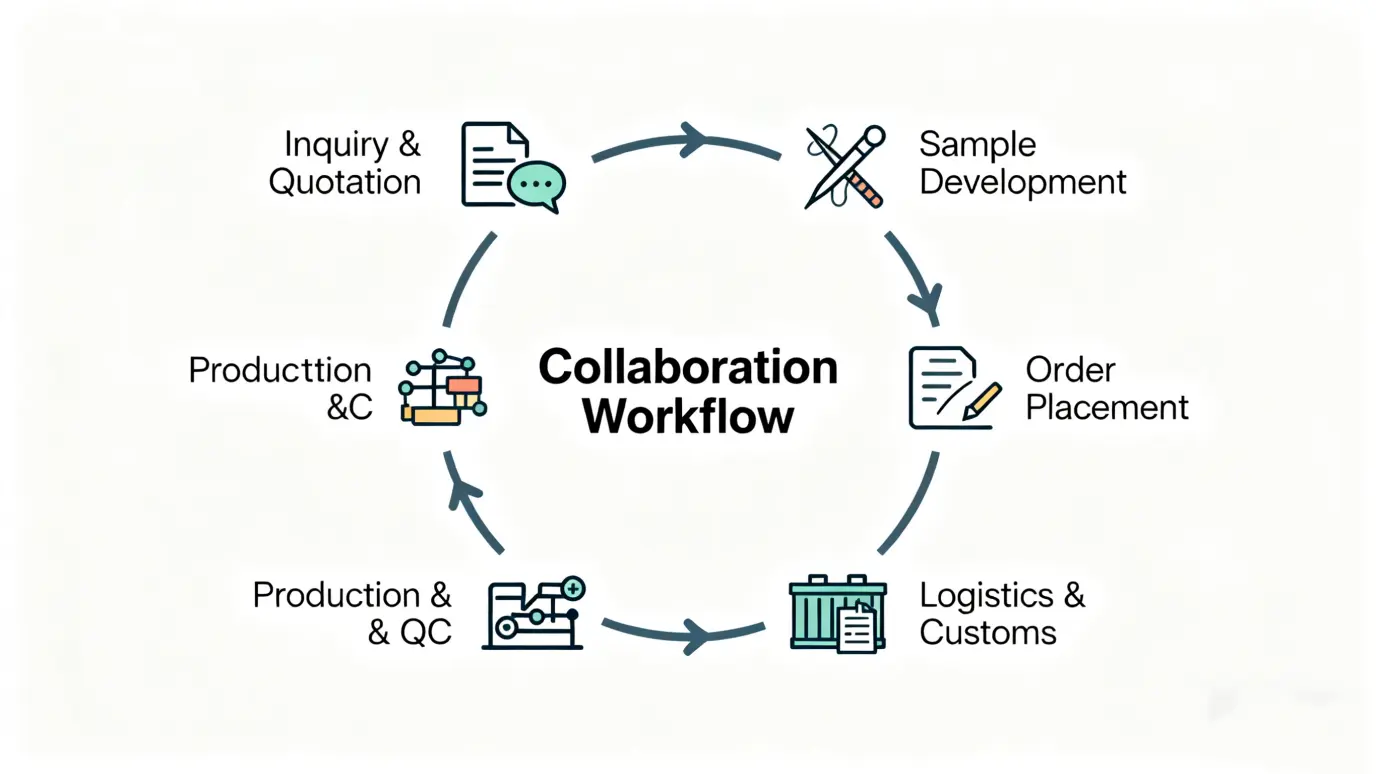

While collaborating with overseas factories can be challenging, following this 5-step process can ensure an orderly and seamless collaboration:

1.Detailed consultation and quote negotiation : First, submit a technical file containing all the technical details of the hoodie design to the supplier, then request a complete quote. The quote should clearly state the unit cost, sample fees, and potential costs such as mold fees and setup fees to avoid cost disputes later.

2.Sample Production and Modification Optimization : Once the price is agreed upon and the sample fee is paid, the supplier will produce and ship pre-production samples. Upon receipt, carefully examine every detail. If any issues are identified, provide detailed feedback via "images + annotations" to ensure the supplier accurately understands the required modifications.

3.Placing a Bulk Order and Confirming Payment Terms : After confirming the final samples are correct, check with the supplier on the total order quantity for each size and color. Chinese hoodie suppliers typically use a "deposit + final payment" payment model. The deposit is typically 30%-50% of the total amount, and the final payment is due upon order completion and shipment. Terms must be clearly defined in the contract in advance.

4.Mass Production and Quality Control : After the factory begins production, suppliers are required to regularly update production progress. High-quality suppliers will proactively send pictures or videos of the production process. Quality inspections are mandatory before shipment. This can be done by a third-party professional inspection agency or by requiring suppliers to provide detailed high-definition images of the finished product. Even for companies with strict quality control, such as China's top custom hoodie Manufacturers, final review is recommended for large orders.

5.Logistics and customs clearance preparation : First, clarify the shipping terms. "FOB" means the factory is responsible for delivering the goods to the Chinese port, while "EXW" requires the brand to arrange for pickup from the factory. The shipping method can be selected based on your needs: ocean freight is cheaper but takes longer (approximately 30-40 days), while air freight is faster but more expensive. Also, understand your country's customs clearance procedures in advance, prepare relevant documents, and budget for import taxes.

4. Core customization direction of hoodies

By collaborating with Chinese hoodie factories , brands can gain a high degree of customization, with personalized designs available from fabrics to packaging:

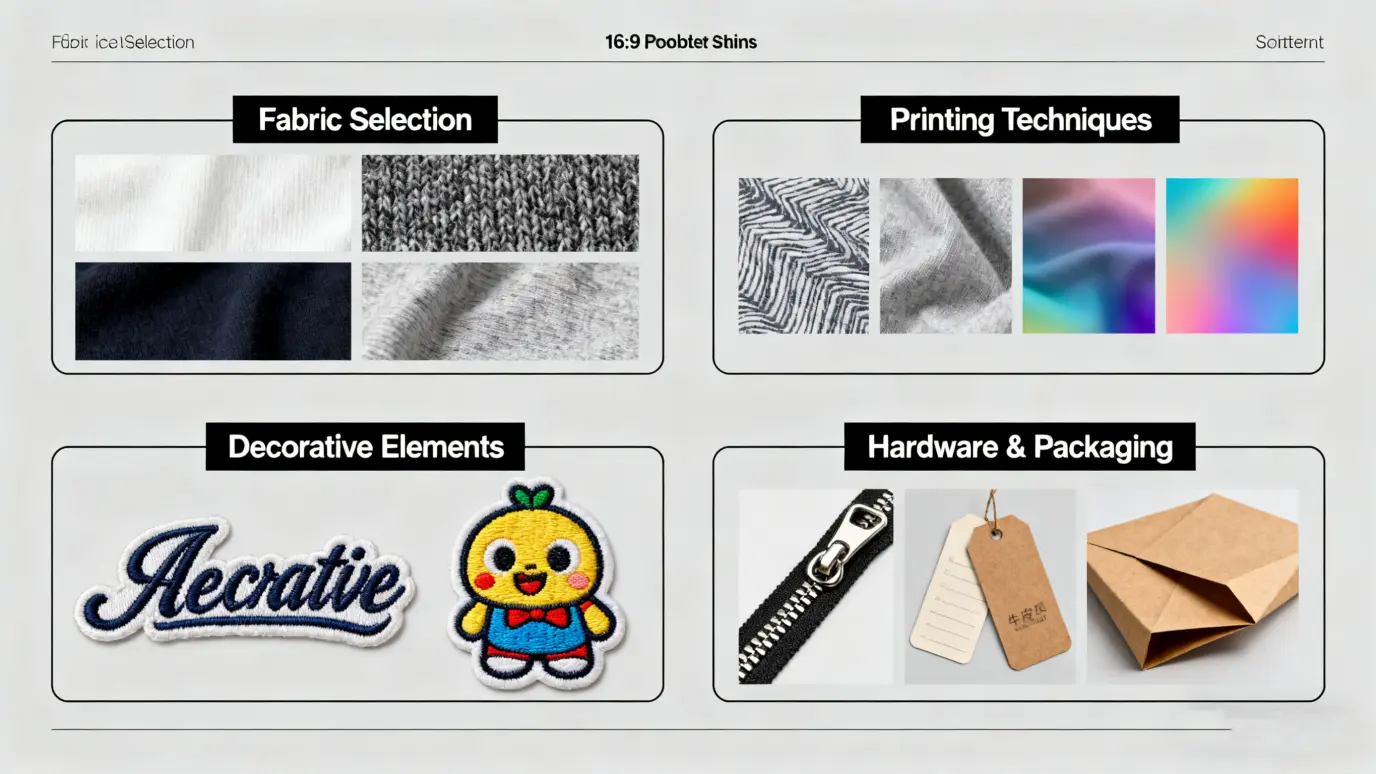

● Fabric selection : Available in a variety of styles, including French terry, fleece, and cotton blends. Pay attention to the fabric weight (measured in GSM/grams per square meter). The higher the GSM value, the thicker the fabric and the fuller the hoodie will feel.

● Printing process : Common processes include screen printing, puff printing that can create a three-dimensional touch, and direct-to-print printing (DTG) suitable for complex patterns. You can choose according to design requirements.

● Decorative elements : Highlight brand logos and design styles through embroidery, appliqués, or custom patches to enhance product recognition.

● Hardware and trims : Zipper style, drawstring metal head (rope head), drawstring hole metal ring (air eyelet) and other details can be customized to create a unique design highlight.

● Labeling and Packaging : Custom woven collar labels, hang tags, and logo-printed plastic bags complete your brand image. For a deeper understanding of the entire garment production process, choose the exclusive services of a professional custom hoodie manufacturer.

V. Conclusion: Partnering with Suppliers to Achieve Brand Success

Finding Chinese hoodie suppliers isn't a matter of luck; it requires a systematic approach with clear processes and meticulous execution. Strong supplier relationships are crucial for a brand's long-term growth.

The key to successful collaboration is clear: first, thoroughly and carefully evaluate suppliers; second, maintain open and frequent communication; and third, strictly adhere to standardized production processes. This combination of factors ensures both product quality and a smooth and efficient collaboration process. While lists of high-quality hoodie manufacturers are valuable as a reference, finding a truly suitable partner is only possible through precise matching of brand needs and establishing in-depth collaboration.

If you’re looking for a reliable partner to bring your brand vision to life, visit SYH -Streetwear and learn how their expertise can streamline your production processes and help your brand grow.