A comprehensive guide to fabric printing services: from idea to finished product

If you have a carefully designed fabric pattern but are overwhelmed by the myriad printing services available, don't worry. With so many different fabric printing methods available, each with its own unique advantages, choosing the most suitable printing method for your project requires careful consideration.

This guide will clear your knowledge gaps. We'll explain the most common printing techniques in clear and concise language. We'll then help you identify the optimal solution based on your specific needs. We'll also detail the entire process, from design preparation to final product acceptance. This guide is your ultimate resource for a deeper understanding of fabric printing services

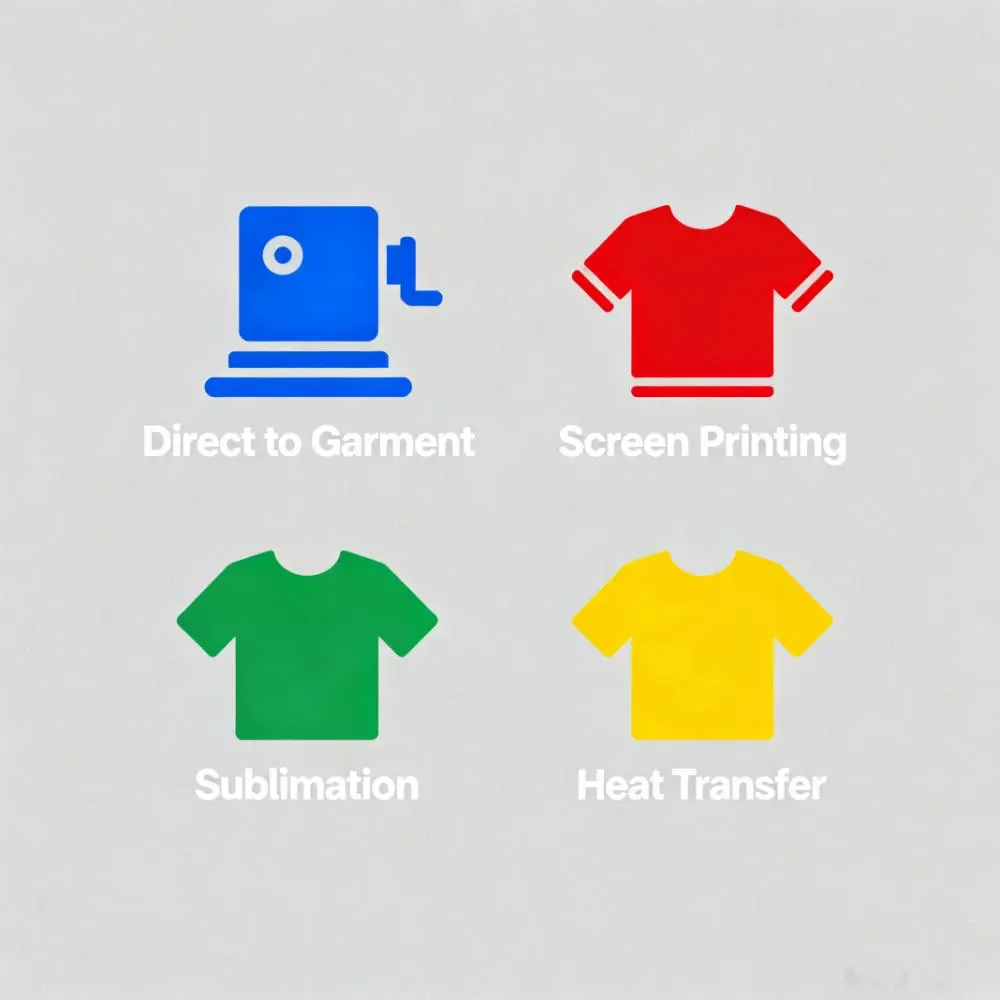

Familiar with core fabric printing techniques

Comprehensive knowledge is essential to making the right choice among the many printing options available. There are four basic methods for fabric printing, each of which is applicable depending on the project type. Below, we'll provide a detailed introduction to each.

Direct-to-garment (DTG) printing

Direct-to-garment printing is like an inkjet printer specifically designed for clothing. The difference is that it prints directly onto the garment. A specialized printer sprays water-based ink onto a T-shirt or other garment, where it is absorbed by the fabric fibers.

This technique is best suited for creating designs with rich color and intricate detail, a good analogy to a poster. It's also a good option for customizing a single piece of clothing, without the high pre-press costs. Natural fabrics like 100% cotton are ideal for direct-to-garment printing.

Screen printing (silk screen)

Screen printing has a long history and remains popular today. The technique uses a stencil called a screen to apply ink to fabric. A separate screen is created for each color in the design. The ink is applied to the fabric through the mesh of the screen in the same pattern, one color at a time.

Screen printing offers a significant price advantage for bulk orders, such as customizing team backpacks or event merchandise. While screen printing offers vibrant and durable designs, the initial cost of screen production makes it less suitable for small orders or designs with rich colors. Distinguishing between different printing techniques requires some background knowledge, and many shops offer guidance on distinguishing between screen printing and digital printing.

Sublimation printing

Sublimation printing is less widely used. First, the design is printed on a special transfer paper. Then, heat and pressure are applied to vaporize the ink on the paper and bond it to the fabric, eventually making the ink part of the fabric.

The finished product of dye-sublimation printing is very soft to the touch, and because the ink is fused with the fabric rather than just adhering to the surface, there is no tendency for cracking, flaking or fading. This process is ideal for creating all-over prints for sportswear or banners, but it is only suitable for polyester or fabrics containing a large amount of polyester.

Heat transfer printing (vinyl/plastic sol)

Heat transfer printing is a method of applying a design to clothing using heat pressing. First, the design is either cut into the vinyl material or printed onto a special transfer paper. Then, a heat press applies high temperature and pressure to bond the design to the clothing.

Flexibility is a key advantage of this method, which can be used on a variety of substrates and is particularly suitable for printing simple graphics, such as adding player names and numbers to sports jerseys or customizing a few personalized T-shirts.

Choosing the best printing method for your project? Comparison guide

Now that you understand the basics of printing techniques, how do you find the method that works best for you? The best choice depends on your clear project goals. Below, we'll introduce printing techniques based on various typical projects. With our help, you can easily choose the ideal printing method for your custom clothing project.

Small batch orders and complex pattern designs

Direct-to-garment printing is the perfect choice for projects like these. For example, if you're testing a design, launching your own brand, or printing photos onto clothing, direct-to-garment printing is the perfect solution. Furthermore, with no set-up fees, customizing a single or limited piece of clothing isn't expensive. And because it allows for multiple colors in a single print, direct-to-garment printing is an excellent choice for designs with extremely intricate details.

Bulk orders and branded peripheral products

Screen printing is the preferred method for these types of projects. If you need to customize 50 or more items, whether for a band, a corporate event, or other promotional campaign, screen printing is the best solution. This custom method allows you to fully meet your needs (for example, bulk orders can result in lower per-unit costs). A custom collection of hoodies is a great example of a screen printing project. For bulk orders, learn about our custom hoodie Manufacturers.

Sportswear with all-over prints

In this case, dye-sublimation printing is the preferred method. This method is well-suited to polyester fabrics, commonly used in sportswear, and ensures a lightweight and breathable fabric. Notably, this technology offers the unique advantage of being able to achieve full-color, edge-to-edge prints all over the garment.

Quick comparison table

Below is a summary table to help you make your decision.

| Printing method | Applicable Scenarios | Applicable fabrics | Color and detail presentation | Durability | cost |

| Direct-to-Garment (DTG) Printing | Small batch orders, photo printing | Cotton, natural fibers | Excellent, full color | good | Medium unit cost |

| Screen printing | Bulk orders (50 pieces and above), simple patterns | Most fabrics | Good, limited colors | Excellent | Low unit cost (for mass customization) |

| Sublimation printing | All-over prints, sportswear | polyester fiber | Excellent, full color | Excellent (no fading) | High unit cost |

| Heat transfer printing | Name, number, simple logo | Most fabrics | good | good | Depends on type |

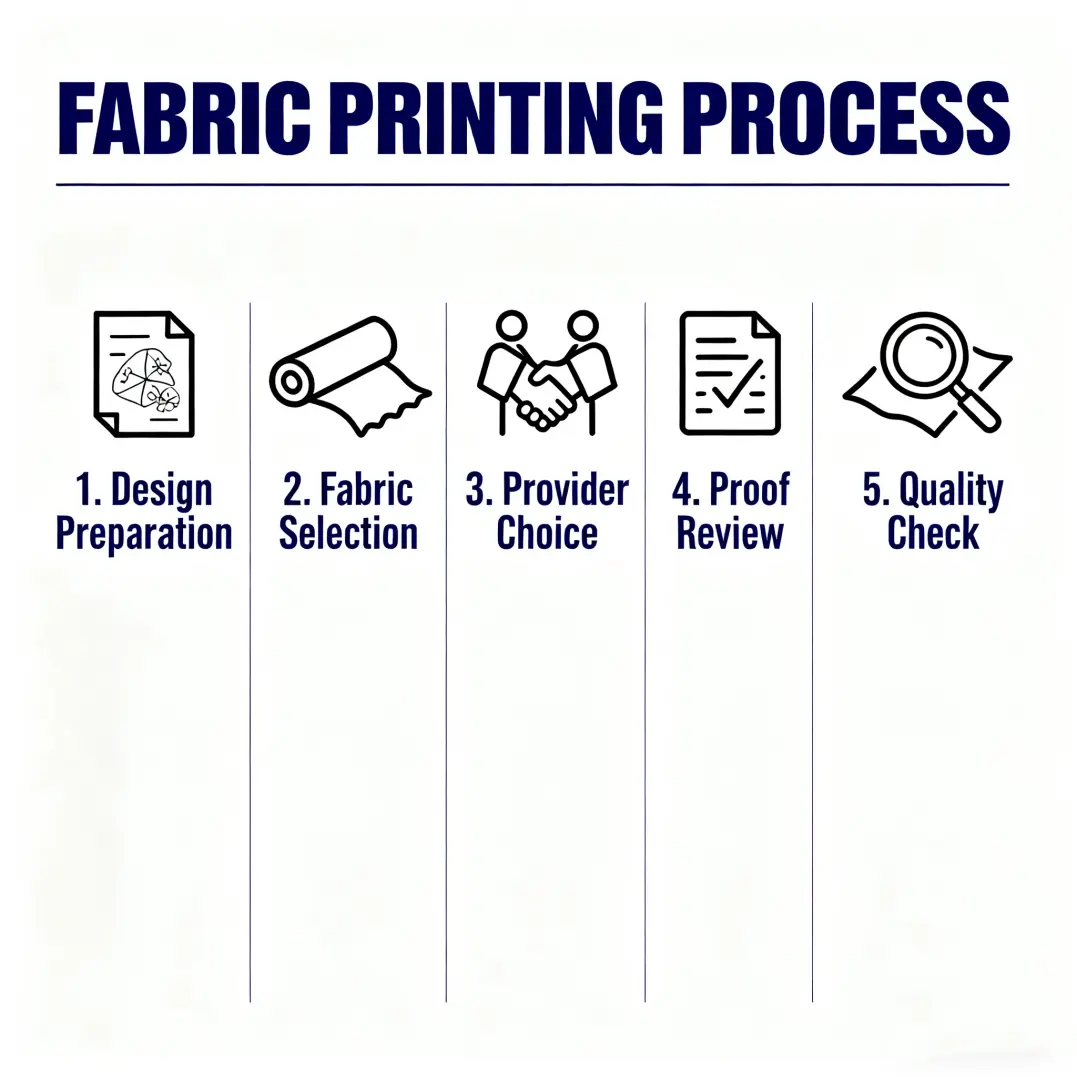

From design concept to finished fabric: a five-step implementation plan

Transforming a design into a finished product can seem daunting, but we've broken it down into five simple steps. Following this plan will help you navigate the entire process and avoid common mistakes. This approach is at the heart of our fabric printing services .

Step 1: Determine the design and prepare documents

This is the most critical step, as the final printing result depends entirely on the quality of the design file. For best results, the design file resolution should reach 300 DPI (dots per inch). A high resolution will prevent the printed image from blurring.

Save your file in a format with a transparent background, typically PNG. This ensures that only the design prints without a white border around it. Also, check the color mode; most printers use RGB, but some may require CMYK. Be sure to confirm your printing service provider's specific file requirements. For a more in-depth look at the technical details of different garment customization techniques, refer to our process overview.

Step 2: Choose fabrics or clothing

It's not just about the material you choose; it also impacts the feel of the final product. After all, we all know that direct-to-garment printing works best on cotton, while dye-sublimation printing is best on polyester. For example, what properties do you want from the material? A soft cotton T-shirt might be perfect for a streetwear brand, while a sports team might prefer polyester apparel.

Step 3: Choose the right printing service provider

Find a partner whose philosophy aligns with yours. Check out their demos, read customer reviews, and understand their service process. It's a good idea to request samples to evaluate print quality before placing a large order. Partnering with a reliable custom fabric printer will yield the best results, especially when quality service is paramount.

Step 4: Review the design sample or confirm the sample

Instead of printing the entire design for your order directly onto the garment, your service provider will provide you with a confirmation sample. This may be a digital image that shows how the design will appear on the garment. Please carefully review the confirmation sample, watching for typos and color variations, and double-check the size and placement of the design. This is your last chance to make any adjustments.

Step 5: Final printing and quality inspection

Once you receive your order, it's time to perform a quality inspection. Randomly sample a few pieces from the batch and carefully inspect them to ensure the print is clear, the colors are accurate, and the placement of the pattern matches the sample you approved. Also, check the garments for any defects. If you find any issues, contact your printing service provider immediately.

Key factors affecting costs

The price of fabric printing varies widely. Understanding the factors that influence cost not only helps you gain a comprehensive understanding of your costs, but also helps you plan your budget and make the right choices for your project.

● Printing method : Screen printing involves the high initial cost of purchasing the screen; direct-to-garment printing, on the other hand, has no startup costs, so the cost per piece is lower with direct-to-garment printing. However, for larger orders, the cost per piece with direct-to-garment printing will be higher.

● Order quantity : The larger the order quantity, the lower the price per piece, which is particularly evident in screen printing.

● Number of colors : For screen printing, a new screen needs to be made for each color, which increases the initial preparation costs; for direct-to-garment printing and dye-sublimation printing, the number of colors usually has no impact on the price.

● Fabric/Clothing Type : A basic t-shirt will cost less than a premium heavyweight hoodie or specialized performance fabric.

● Print size and placement : A small logo on the chest will cost less than a larger graphic on the back. Printing in multiple locations (like on the sleeves or back) will also increase the cost.

● Lead Time : If you need your order quickly, most companies will charge a expedited fee to speed up production.

Join SYH Streetwear for shared success

Choosing the right fabric printing service is more than just choosing ink and fabric. It’s about finding a partner who can help you realize your brand vision, a partner with the expertise to produce high-quality garments.

At SYH Streetwear, we pride ourselves on being the bridge between new and established brands, bringing their creative visions to life. As true streetwear enthusiasts, we believe our products must meet the highest standards in craftsmanship and print durability. For every project, we prioritize the finest fabrics and employ the right techniques. We're more than just a printing service provider; we're your growth partner, a trusted partner who can help you build your brand from the ground up.